Traces of our evolution

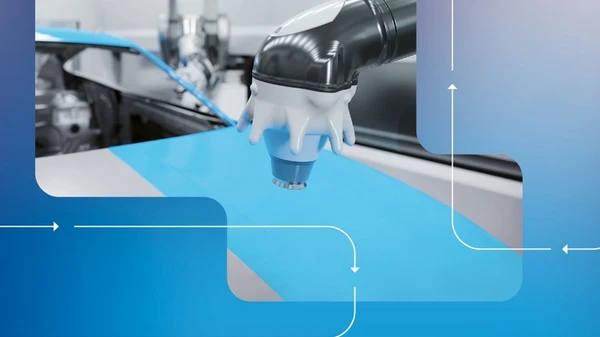

Everything used to be done by hand, then machines took over, now AI is gaining ground.

Dürr & More

Informative articles, exciting interviews, videos, graphics and image galleries: In our Dürr & More online magazine, you will find out more about the Dürr Group in a more relaxed format, and with a focus on current topics.

Browse our collection of articles

Contact

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany