Unbalance as a quality criterion

Schenck offers customers high-quality tire balancing equipment made by joint-venture partner Nagahama

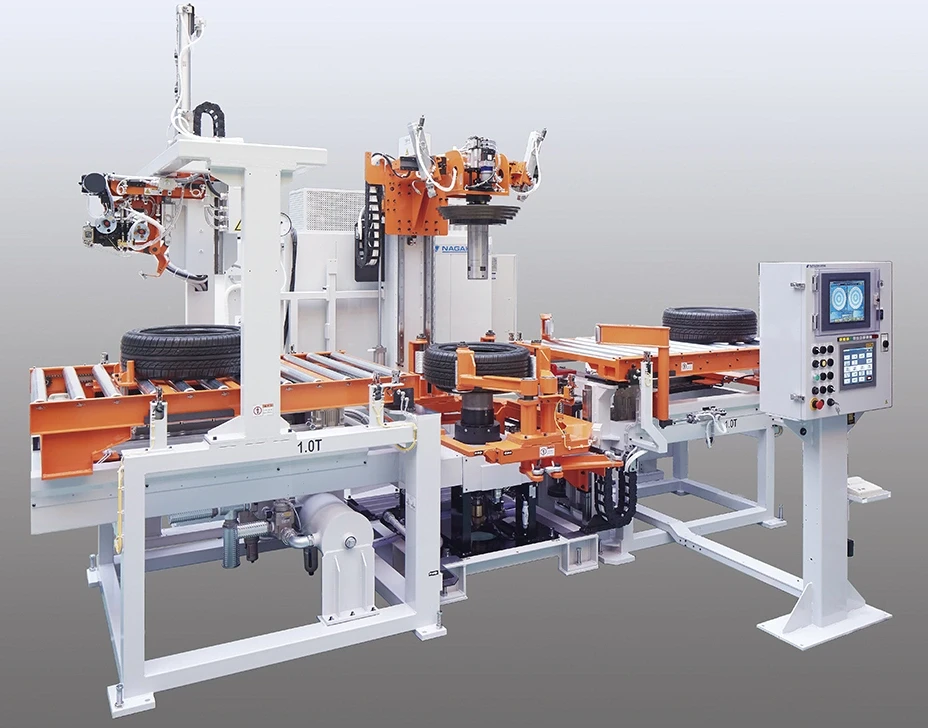

Schenck RoTec, a subsidiary of the Dürr Group, has stepped up its collaboration with long-term joint-venture partner Nagahama Seisakusho in Japan. Now the Darmstadt-based mechanical engineering firm can also provide high-quality balancing equipment for tires to customers in Europe, India and in the United States. Nagahama has already supplied over 200 of these machines to customers.

In everyday language, we talk about “tire balancing” but what we normally mean actually is wheel balancing. A wheel is the combination of the wheel rim and the tire mounted on the rim. The two are balanced as a unit to ensure vibration-free and comfortable running. Schenck produces an assembly line in which digital process control technology is combined with automation and robot technology, as well as with a tire-inflation system and balancing equipment.

Before the assembly of tires both components are checked for unbalances during the manufacturing process in order to meet the high quality requirements for the complete wheel. Nagahama's tire balancing machine thus offers a perfect addition to the Schenck RoTec product portfolio.

Until now, the machines have been sold mainly in the Asian region, where many tire manufacturers maintain production locations. Meanwhile tires are once again increasingly being manufactured in Europe, China and the United States. This is due on the one hand to new trade restrictions and, on the other, to the fact that tires have to meet ever higher quality specifications.

A partnership with a long tradition

Nagahama Seisakusho Ltd., headquartered in Takatsuki City (Osaka) was established in April 1948. The company with a workforce of around 120 employees has another production location in Hamamatsu, and a distribution office in Tokyo.

In the last financial year, Nagahama Seisakusho achieved sales of around 38 million euros, with a clearly positive operating result. About 85 percent of sales are accounted for by business with the automotive sector (primarily Japanese car and truck manufacturers like Toyota, Honda, Nissan). EBIT (earnings before interest and taxes) amounted to 4.7 million euros.

Carl Schenck AG, a holding of the MPS division which also includes Schenck RoTec, has a 50-percent stake in the Japanese engineering company. The joint venture has already been in existence since 1970.

Checked twice – tried and tested many times over

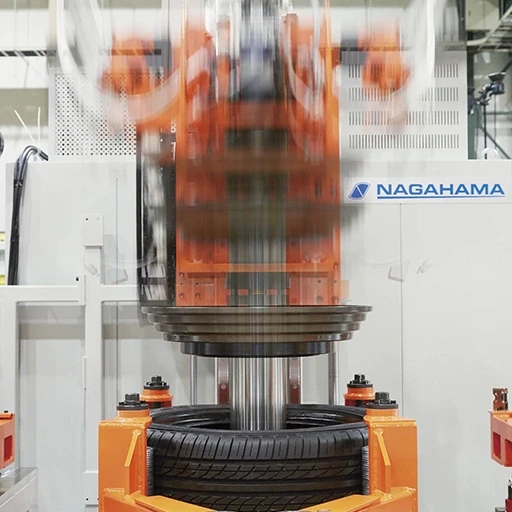

Schenck is perfectly placed to meet these high requirements. During balancing, a machine picks up the tires in a special measuring rim and inflates them with air. The subsequent measuring run determines the unbalance under real conditions. The tires are then classified into different grades, indicated by a mark on the side of the tire. To check whether the tires roll uniformly, an upstream uniformity station has been integrated into the line. Here, an optical measuring system identifies any geometrical deviations, depressions or bulges in the tire.

Patrick Manske, Product Manager at Schenck RoTec, explains: “Using the tire balancing machine and upstream uniformity station, we can now offer complete tire grading lines. These tire grading lines are well proven in the tire industry and allow a comprehensive assessment of the tires for maximum reliability.”

Flexible multi-layer tires in particular are inspected carefully: In the final production step during tire manufacture, the so-called “final finishing,” the tires are x-rayed to detect any internal damage, for example to the carcass. In addition, the uniformity and unbalance, including geometrical deviations, are determined in this step.

Furthermore the quality grade of the finished tire is determined and a classification is made on the basis of this data. Depending on the quality grade, the tires are later supplied to various markets.

Our tire grading line enables customers to perform a comprehensive tire assessment for maximum reliability.

Patrick Manske, Product Manager of Schenck RoTec

Landwehrstr. 55

64293 Darmstadt

Germany