Automotive body shop and paint shop operations are highly automated nowadays. A modern Dürr paint shop includes a good 100 robots. Final assembly systems, on the other hand, feature a significantly lower level of automation since many processes are complex and require flexibility. The automotive industry is expecting HRC concepts to accelerate the automation of final assembly operations and thus increase production efficiency.

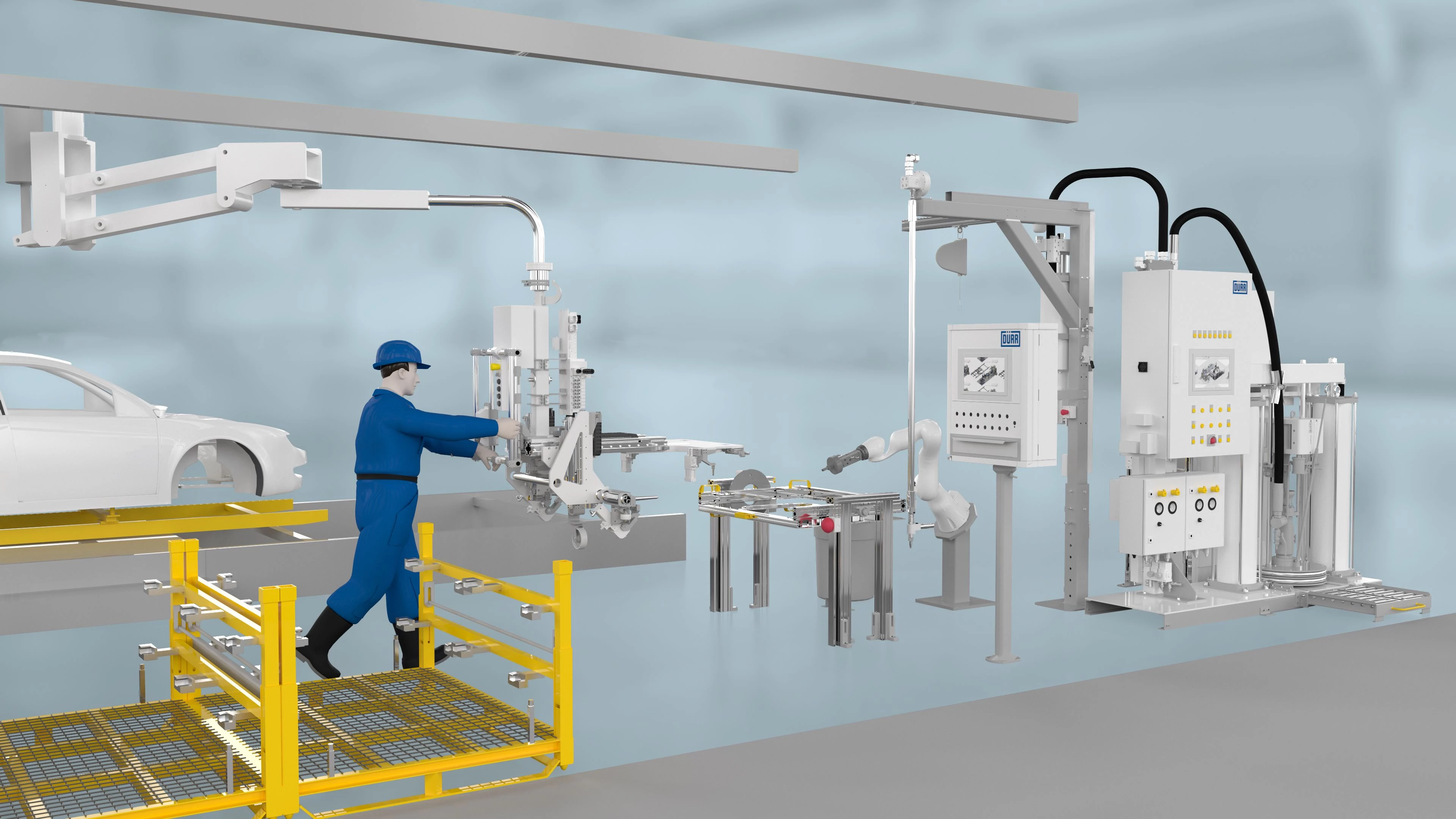

In Dürr’s HRC concept for tank fitting a skilled worker moves the tank to the workplace and cleans it. A robot equipped with an applicator for adhesive then takes over. It applies a bead of adhesive to the edge of the tank in the predefined cycle time. Sensor monitoring ensures that the bead is absolutely uniform. The skilled worker then attaches the tank precisely in the body.

Dürr developed the entire robot cell for this process. This includes, for example, the material feed, the dispensing technology for a controlled adhesive flow, and the control unit. Particular importance is attached to the issue of safety. The robot is positioned such that contact with the human colleague is more or less ruled out. Should contact occur nevertheless, the robot, which is equipped with multiple sensors, comes to a standstill within milliseconds. The robot operates slowly, using rounded components and always below head and chest level.

Ralf W. Dieter, CEO of Dürr AG: “We see great potential for human-robot collaboration concepts. Our customers will benefit from lower unit costs, the physical demands on the workers in final assembly will be reduced, and the workers can concentrate on demanding tasks which require situation-related thinking and flexibility.”