The two new applications were developed in Dürr’s Digital Factory. In addition to the ADAMOS IIoT platform, they form another milestone in the digitization of production processes. Says Dürr CEO Ralf W. Dieter: “Our digital innovations are turning paint shops into smart factories. The new products include both current software technologies and Dürr’s special expertise in the painting process. This is how we are offering efficient solutions for the smart networking of the painting process.”

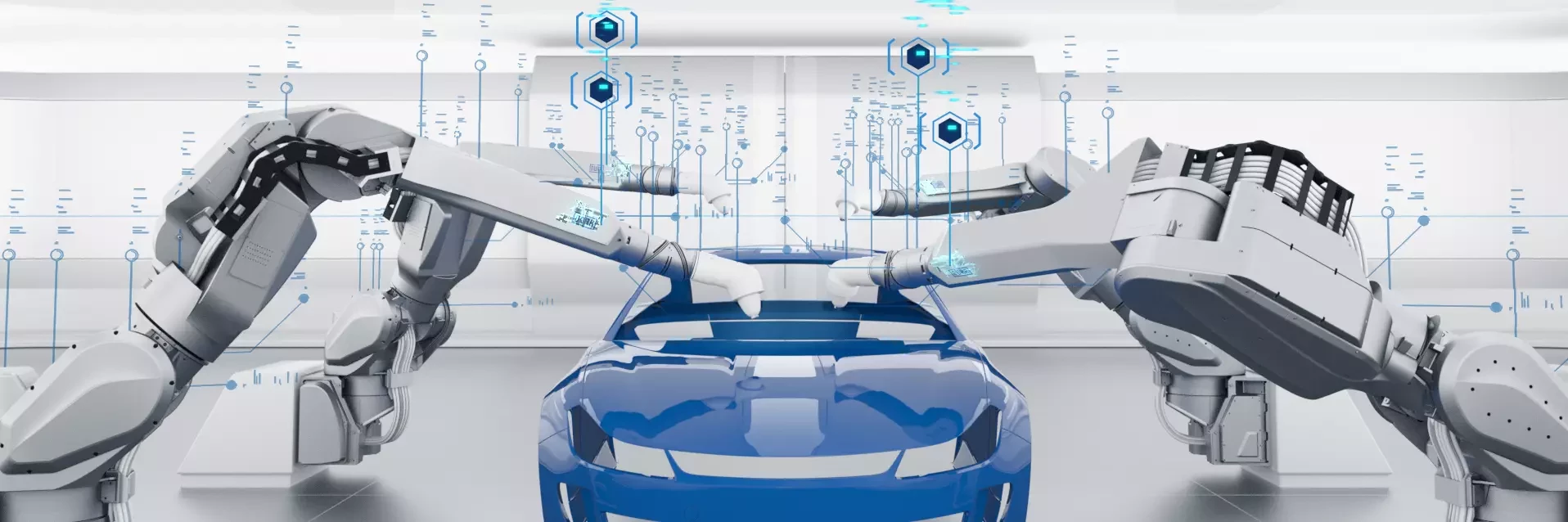

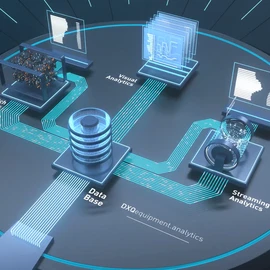

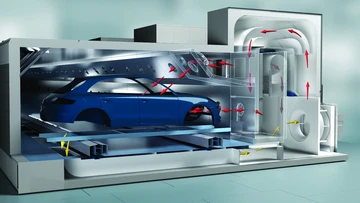

The EcoScreen Equipment Analytics software seamlessly records all data from the painting process. Based on this, a ‘digital fingerprint’ is created for every painted car body. It contains information, for example, on the robots’ movements, on paint consumption, and on the exact position of the car body during painting. If a quality problem occurs, the cause can be determined immediately using the recorded data. The plant operator can perform analyses for any painted car by projecting the path taken by the painting robot onto the CAD model of the car body on the screen.

The Streaming Analytics function of EcoScreen Equipment Analytics is used, for example, for online quality control during the painting of cars. Here, in real time, algorithms analyze data from the painting process, such as paint flow, and show anomalies. This enables the operator to react immediately, thus preventing further car bodies from being painted incorrectly. The algorithms can easily be created by means of a graphic user interface – without any programming knowledge.

The Streaming Analytics application is already being used in the paint shop of a German automaker. It is based on a software module from the ADAMOS IIoT platform. Dürr is currently working on the integration of a Batch Analytics function in EcoScreen Equipment Analytics. Here, the software analyzes historical data, detects trends, and uses artificial intelligence to develop predictions and recommended actions.

The second new application, EcoScreen Maintenance Assistant, supports customers in their maintenance activities. In large automotive paint shops, there are thousands of components to be serviced, such as pumps, valves, filters or sensors. The EcoScreen Maintenance Assistant keeps a record of every component. It shows maintenance dates, provides access to instructions, prompts completed work acknowledgement, and prepares a maintenance history. One unique selling point is that the software not only signals fixed maintenance intervals, but it also works on a cyclical basis. This means it counts how often a component has been used and calculates the remaining operating time. For this purpose, it accesses the controls in the paint shop to retrieve usage data.

The EcoScreen Maintenance Assistant is already being used in several automotive paint shops. Going forward, the application should also indicate predictive maintenance requirements. To this end, it will be linked to the EcoScreen Equipment Analytics software. This uses special algorithms to check for wear and tear of components, and transmits the result, along with a relevant maintenance task, to the EcoScreen Maintenance Assistant.

The two new applications are products developed by the Digital Factory. Founded at the beginning of 2018, this organization has cross-departmental software experts working on solutions for the digitization of production processes.