- Chinese manufacturer FMC orders paint shop for its Byton brand

- Further growth expected with e-mobility production technology

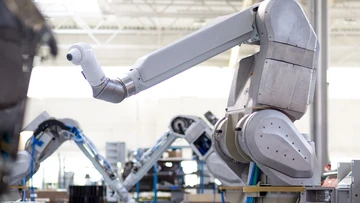

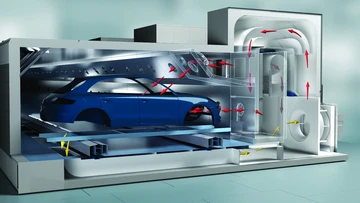

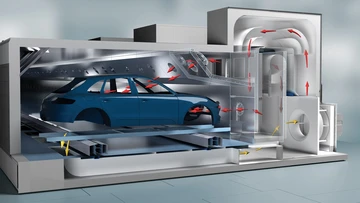

Byton stands for electric, networked and highly automated driving. FMC also uses the latest standards in its manufacturing operations. The paint shop, which was ordered in the first quarter of 2018, will be equipped, e.g., with the new EcoInCure technology for curing freshly applied paint. EcoInCure reduces the space required in Nanjing by 20 % and heats all car body parts evenly. For modern vehicles, in which materials such as steel, aluminum and composites are combined, this is an important factor and crucial to ensuring quality. Paint application at FMC in Nanjing will be performed automatically using robots. Production start for the paint shop is scheduled for October 2019.

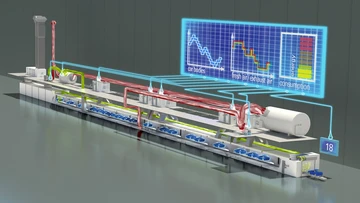

In 2017, Dürr already achieved sales of around € 250 million from production technology for electric cars. Going forward, the company expects this figure to increase substantially. Ralf W. Dieter, CEO of Dürr AG: "Electromobility is still in its infancy. As production grows, so will the demand for the necessary manufacturing systems. We are prepared for this – not just in painting technology, but also by offering highly automated solutions for the final assembly, filling and testing of e cars." In final assembly, in particular, production processes will change as a result of e-mobility, since the power train of battery-operated e-cars is less complex than that of vehicles with combustion engines. This enables a higher level of automation in assembly.