EcoInCure: A revolution in car body drying

Product manager Heiko Dieter talks about the strengths of Dürr's new oven

Dürr's EcoInCure dries complex car bodies faster and more gently while providing a better paint quality than conventional ovens. In the following interview, product manager Heiko Dieter explains why the new design is particularly suitable for future vehicle concepts and why EcoInCure offers a major potential for savings in greenfield as well as in brownfield projects.

WHAT FIRST PROMPTED THE DEVELOPMENT OF ECOINCURE?

With → EcoInCure Dürr is breaking new ground. The curing concepts previously established on the market did not have much scope for improvement in terms of paint quality and drying performance. With the idea of drying from the inside out, our R&D engineers have taken a simple yet effective approach and followed through on it. The result is a concept that revolutionizes car body curing.

THAT'S A BOLD CLAIM! WHAT EXACTLY MAKES THIS OVEN SO UNIQUE?

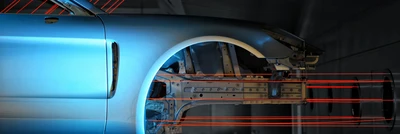

→ EcoInCure provides significantly improved top-coat quality and a process performance easily surpassing that of conventional ovens. This is achieved through the inflow of hot air through the windshield, thus heating the car body panels from the inside out. This reduces the risk of pinholing, since the paint layers are heated from the bottom. Therefore, the film on the paint surface only forms once the residual moisture and solvent have completely evaporated.

EcoInCure minimizes flow velocities around the freshly painted surface. This ensures an undisrupted top coat appearance and an unrivaled surface quality. The excellent heat transfer at the mass parts of the car body ensures unprecedented uniform and rapid heat-up. Temperature differences within the car body can thus be reduced by 50 percent and heating times by an impressive 30 percent. This is achieved by only two nozzles with long discharge ranges directed through the windshield, and two nozzles directed into the opening of the engine compartment.

Fit for future vehicle concepts: EcoInCure enables us to dry complex car bodies faster and more gently, while providing a better paint quality.

Heiko Dieter, product manager

AND TO THIS END, THE CAR BODIES ARE MOVED THROUGH THE LINE TRANSVERSELY?

Exactly! This clever trick enables us to reduce the distance between the nozzles and the vehicle. At the same time, the windshield is the only vehicle opening whose orientation to the nozzles does not change. This makes it possible to cure many different types of car body reliably. The stop-and-go operation ensures that the car body is perfectly positioned in relation to the nozzles.

HOW DOES THE TRANSVERSE ORIENTATION AFFECT PAINT SHOP LAYOUTS?

The oven is only half as long. This alone leads to compact layouts and offers further potential for the design. Aside from the efficient connection of the conveyor system, it is often possible to dispense with an entire story of a building. This can save millions of euros. → EcoInCure can also replace existing double or u-shaped ovens in brownfield plants. This paves the way for capacity expansion or increased process requirements such as bake hardening.

HOW DOES THIS OVEN ENABLE DÜRR TO POSITION ITSELF FOR THE CHALLENGES OF FUTURE VEHICLE CONCEPTS?

Electromobility will lead to a number of changes in the body shop. To protect their batteries in the event of a crash, car bodies of electric vehicles require reinforced rocker panels and more stable structures due to the weight. This places higher demands on the heating process, an area in which → EcoInCure is unrivaled. Innovative car body concepts, where steel, aluminum or composites are combined, make it necessary to heat all components absolutely evenly to prevent thermal component stresses. EcoInCure also manages this like no other oven with minimal temperature differences. The same goes for glued car bodies. Also benefiting from EcoInCure are car bodies made of bake-hardening steel, which undergo additional heat treatment in the EC oven. Where conventional ovens reach their limits, EcoInCure offers significant process reserves thanks to the faster heat-up process. This is another reason why the oven is so interesting for modification projects of Brownfields.

HOW DOES ECOINCURE FIT INTO THE DIGITAL@DÜRR STRATEGY?

Dürr has been offering smart products with its ovens for a long time. In the case of → EcoInCure, our R&D engineers have come up with even more highlights. Here it is worth mentioning the digital quality card. This enables the operator to model all heating parameters for a specific car body using a digital twin, and document these as proof of quality. In addition, it is possible to identify imminent faults automatically within seconds, which ultimately prevents production losses. Furthermore, → EcoSmart VEC offers variable fresh- and exhaust-air control. This additionally reduces the consumption of natural gas and electricity by up to 50 percent during partial-load phases or production downtimes. In many cases, it already pays off during the run-up phase of a new paint shop.

WHAT CAN YOU TELL US ABOUT THE STATUS OF THE MARKET LAUNCH?

→ EcoInCure has been available to our customers as a product since 2017. It attracts a high level of interest. Aside from well-established carmakers like Skoda, which is using EcoInCure for the first time in its paint shop in Mlada Boleslav (Czech Republic), we have also seen lots of interest from new automotive manufacturers in Asia. Impressed by the benefits in terms of paint quality and production efficiency, EV manufacturer Byton is one of the companies that has decided to use EcoInCure in its new paint shop. The first three paint shops with this innovative oven will go into operation as early as 2019. Further projects are already being planned.

Find out more...

... about → EcoInCure.

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany