Sealing – Faster and of better quality

Oct 18, 2019

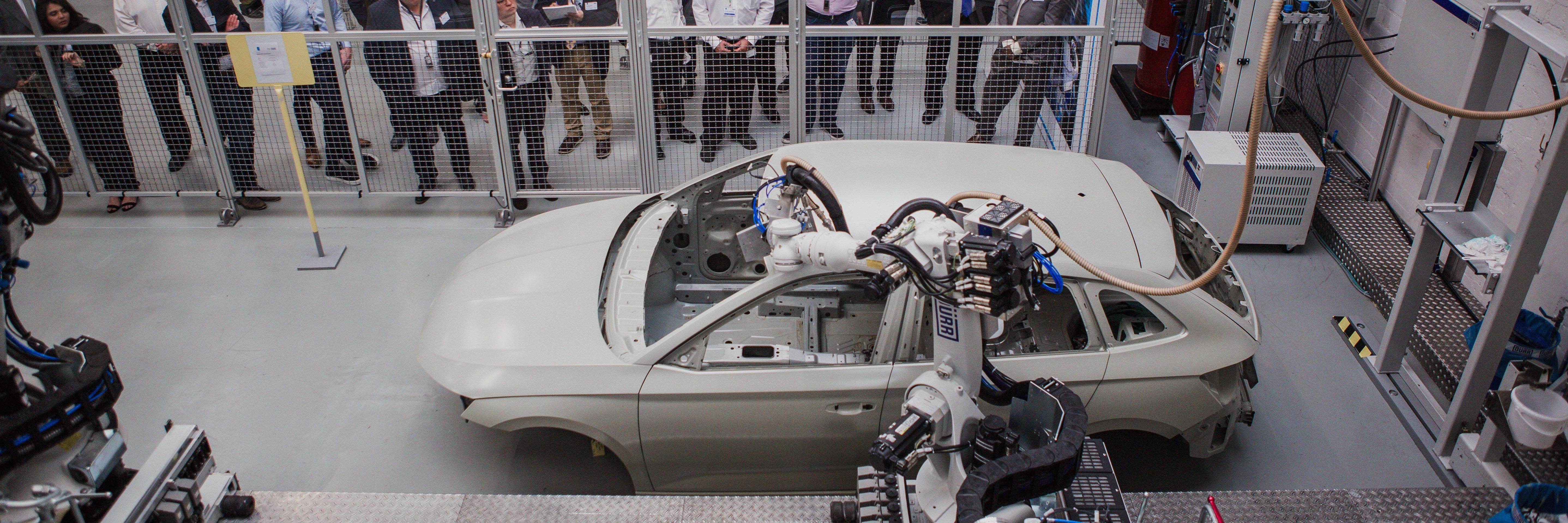

New technologies for fully automated process efficiency

Weather the new EcoJet ST multi-jet nozzle, which seals standing seams in just one pass, the EcoJet SE wide-slot nozzle, which applies underbody protection without any overspray, the new nozzle changing system, which ensures maximum flexibility and robot utilization at the same time, or the automated roof seam application system with integrated vacuum forming, that provides visually perfect seals – Dürr presented several innovations in the field of sealing.

EcoJet ST meets the challenge of reliably sealing standing seams in just one pass. It does this by producing three streams from one nozzle, which wrap around the seam and merge perfectly.

Advantages:

- Conventional methods require either two work passes or manual rework. Since the EcoJet ST does not require the second work step, the time required for the application of standing seam is halved.

- The robot application ensures higher quality than manual rework. Since the coating precision eliminates air inclusions and blistering.

- The EcoJet ST is compatible with all common PVC materials and can be retrofitted in existing plants.

The EcoJet SE is responsible for the fully automatic overspray-free application of underbody and sill protection. The special wide-slot nozzle applies strips up to 150 mm wide evenly in the required coating thicknesses in the flat stream method.

Advantages:

- The application takes place at a high speed and in short cycle times.

- Compared to airless application, the flat stream method is much less expensive. It does not require enclosed booths, which means that there is no need for equipment to regulate the air balance and the cost for ongoing cleaning.

- The nozzles require up to 30% less energy to produce a flat stream and have up to five times longer service than an airless nozzle.

As various as the tasks in sealing are, so wide is the range of nozzles. The more than 360 different versions that Dürr has currently in its range enable the application from delicate seams to wide strips for flat applications. The newly integrated nozzle changing system ensures high flexibility in application systems and maximum utilization of the sealing robots.

Advantages:

- The compact technology is fully integrated in the EcoGun2 3D applicator.

- Whereas previously it was only possible to change one nozzle per cycle, now the entire nozzle head with three nozzles can be changed at once. This saves times, increases flexibility and works very simply.

- The compact, vertically positioned storage for the nozzle changing system provides space for up to six different heads with a total of 18 nozzles, enabling maximum variety. Additional shelves can be added if required.

The roof seam sealing system with vacuum forming is another innovation in the area of sealing. Here, the roof channel is initially filled with PVC and then the excess material is removed by vacuum suction cups. The design of the roof seam is shaped in such a way that it can be painted directly.

Advantages:

- The fully automated application requires no manual rework or masking.

- The roof seams are applied visually perfect.