Green Technology Center opened

Nov 28, 2024

Services relating to the development and production of rotors

Rotor testing, spin tests, burst analyses, process consulting, and validation — at the new Green Technology Center, Schenck RoTec offers a wide range of services relating to the development and production of rotors, for example for electric motors. This provides suppliers to the automotive, aerospace, and general mechanical engineering industries with important insights for the optimization and further development of their products.

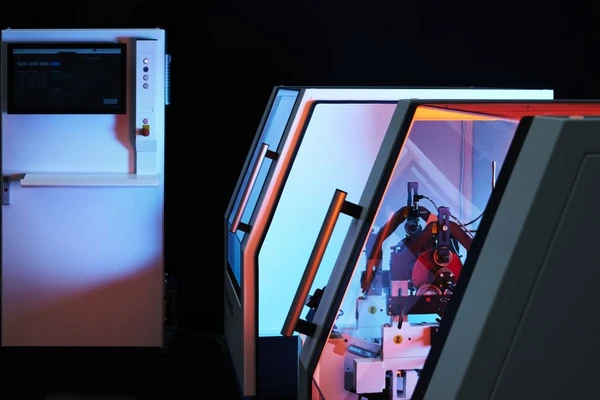

The Dürr Group subsidiary Schenck has bundled its test facilities at the Green Technology Center in Darmstadt (Germany). This enables more efficient processes and significantly speeds up the turnaround times for rotor testing. Customers, in turn, benefit from shorter development cycles. Thanks to the modern machine equipment, tests can be carried out on a customer-specific basis and adjustments to the test sequence can be made quickly and flexibly, if required. This increases product quality.

The Green Technology Center forms the center of an entire network of similar services that Schenck, as a global company, also offers in the USA, Japan, and China.

It is equipped with four different spin test systems. After the spin tests, the rotors are examined in a specially equipped measuring room. Here, deformations of the rotors resulting from the spin tests are precisely analyzed. In an upstream room, the parts to be measured are brought to the stable temperatures required for the measurement. This measuring room also plays a very important role in the metrological traceability of unbalance-specific measurands in Schenck RoTec’s accredited test laboratory for balancing technology. In particular, the test laboratory has a globally unique accredited reference system for the measurand unbalance itself. The test laboratory is considered to be leading in the technology for the metrological qualification of balancing and centrifugal systems.

Consulting service at all stages of production

In the Green Technology Center, four balancing machines can also be used to detect and correct any unbalances directly on site. The experienced technical consulting team advises customers in all phases of rotor production: both during the design and testing of prototypes through to series production and production optimization.

The Green Technology Center demonstrates Schenck’s commitment to climate-friendly mobility.

Dietmar Heinrich, CFO of Dürr AG

Technological innovation, customer orientation, and commitment to climate-friendly mobility — this is what Schenck’s new Green Technology Center stands for, said Dietmar Heinrich, CFO of the Dürr Group. “We recognized the potential of electromobility early on and decided to expand this future-oriented business area in a targeted manner. The opening of the Green Technology Center is a further step in this direction,” he said. Furthermore, he thinks that the climate-friendly nature of electromobility makes it an excellent fit with the sustainability-oriented corporate strategy.

Rotors for the automotive industry are not the only products examined at the Green Technology Center. Promising drive concepts for the electrification of aviation and rotating components relating to the use of hydrogen are also subjected to various endurance tests.

Facts about the project

- Total area of the Green Technology Center: approx. 940 m², including 140 m² air-conditioned measuring room

- Machinery: 4 spin test systems, 3 measuring machines, 4 balancing machines

Impressions of the opening

Holger

Mayer

Global Director Digital and Marketing

Schenck RoTec GmbH

Landwehrstr. 55

64293 Darmstadt

Germany

Landwehrstr. 55

64293 Darmstadt

Germany