Digitalization for our customers

In the digital factory, the software engineers and control technicians from the development teams of all divisions in the Dürr Group work hand in hand for our customers. Since 2018, the company's digital experts have been working on new digital solutions to optimize processes and products. The Dürr Group combines software competence and expert knowledge of production technology and manufacturing processes – an advantage over pure software providers.

Dürr Group's digital factories

There are about 400 software experts working on digital development projects. Instead of researching side by side, they work together towards common goals. This increases the effectiveness of software and control development and makes it much faster and more efficient. Speed counts in the race to see who will shape the connected world of the future.

→ Learn more about how we work in the digital factory

→ Would you like to be part of the digital factory? Apply now!

Digital products in our online magazine Dürr & More

Read more about the digital products of the Dürr Group in the following Dürr & More articles.

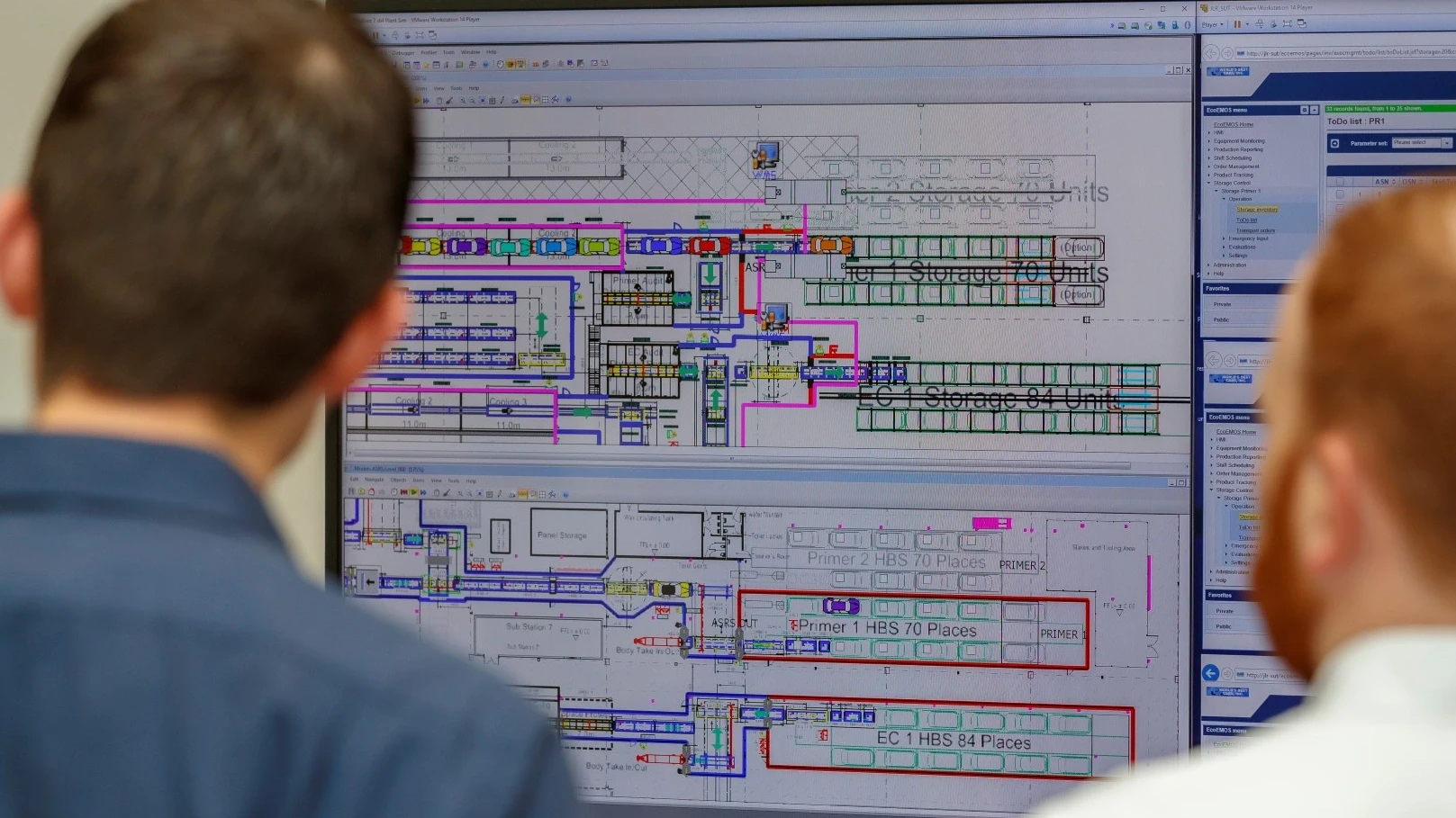

DXQ – Digital Intelligence by Dürr

Tailored software solutions for plant operation, analysis, and control (MES).

→ Read more

Digital toolbox

Specially tailored smart helpers bring digital transformation to small workshops.

→ Read more

Next level balancing

Intelligent software solutions help unlock the full potential of production and machine data.

→ Read more