New generation of robots from Dürr

More versatile painting through additional movement options

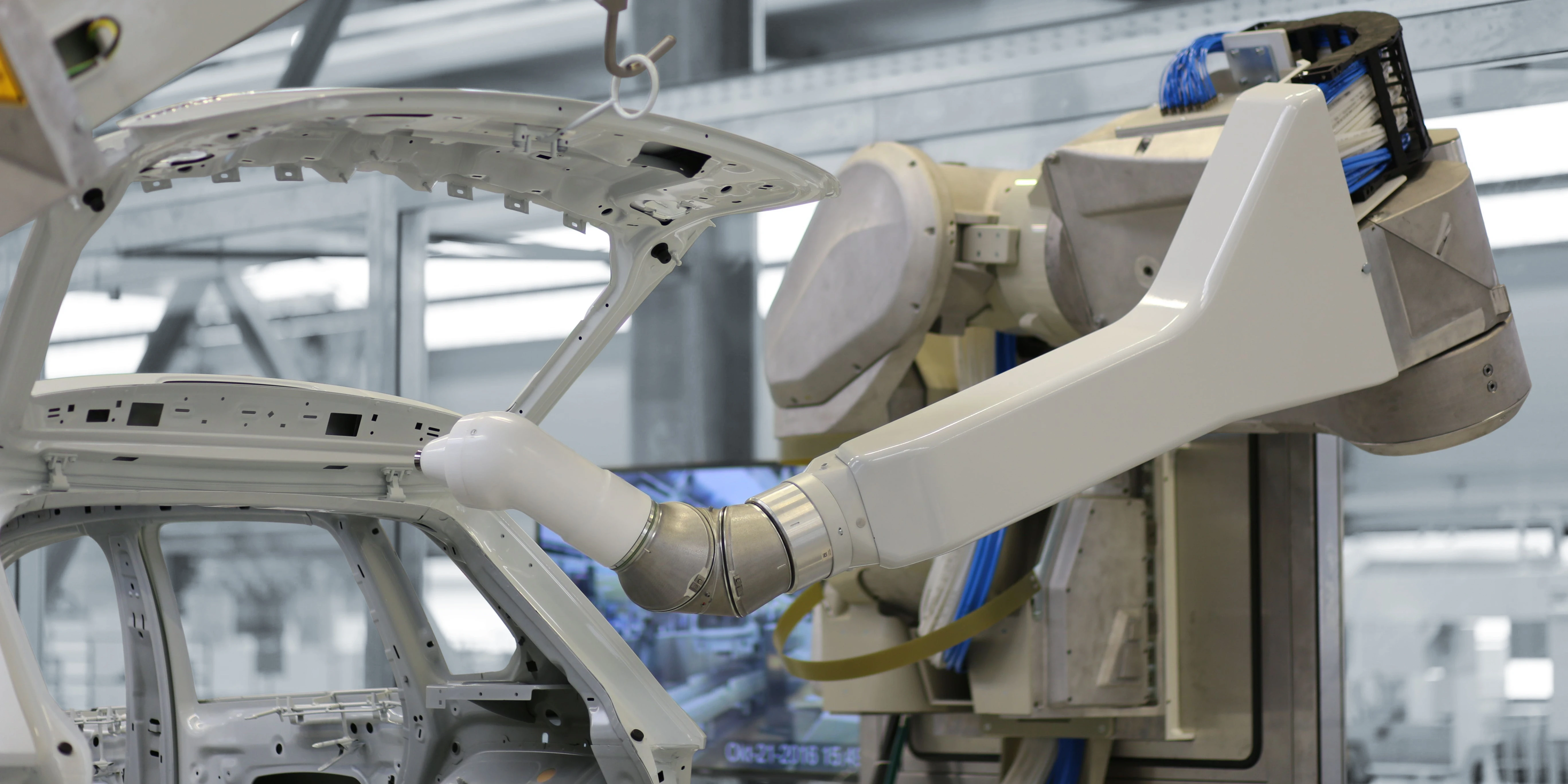

The new Ecopaint Robot generation from Dürr scores high with many innovative functions for the automated painting process. Thanks to its greater kinematic freedom, the EcoRP E043i model with its seven-axis kinematic system enlarges the work zone and can often be used instead of a solution with linear displacement rail.

This can significantly reduce investment and maintenance costs in the paint booth. Another newly developed product, the→EcoRCMP2 robot control, is a key module of the Smart Factory.

Paint robots are usually equipped with six axes. A displacement rail in the booth wall ensures that the robot can move parallel with the car body in the paint booth and thereby reach all car body areas.

Greater mobility through seven-axis kinematic system

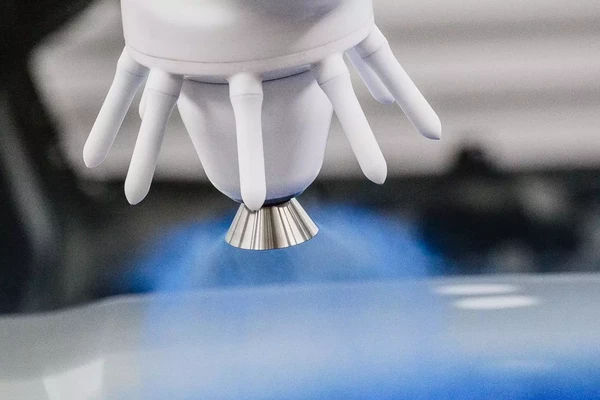

Dürr has now decisively advanced the familiar concept with its new robot generation. “The new → EcoRP E043i from our third robot generation has been equipped provided with a seventh rotatory axis. This significantly increases flexibility and versatility,” explains Dr. Hans Schumacher, President & CEO of Dürr Systems AG. The seventh axis is directly incorporated into the robot’s kinematic chain, thereby increasing the freedom. Particularly in interior painting, this improves access to many areas and avoids collisions with the vehicle. Thanks to the new, optimized control system, the 3rd-generation Dürr robot moves along the car body in a uniform and with even more harmonious painting paths.

“Omitting the displacement axis produces clear advantages for our customers in terms of investment costs or space consumption, particularly when converting existing paint shops, but this also reduces maintenance and operating costs later on,” says Dr. Schumacher.

The new robot generation has been equipped provided with a seventh rotatory axis. This significantly increases flexibility and versatility.

Dr. Hans Schumacher, President & CEO of Dürr Systems AG

Six or seven axes: the right solution for every application

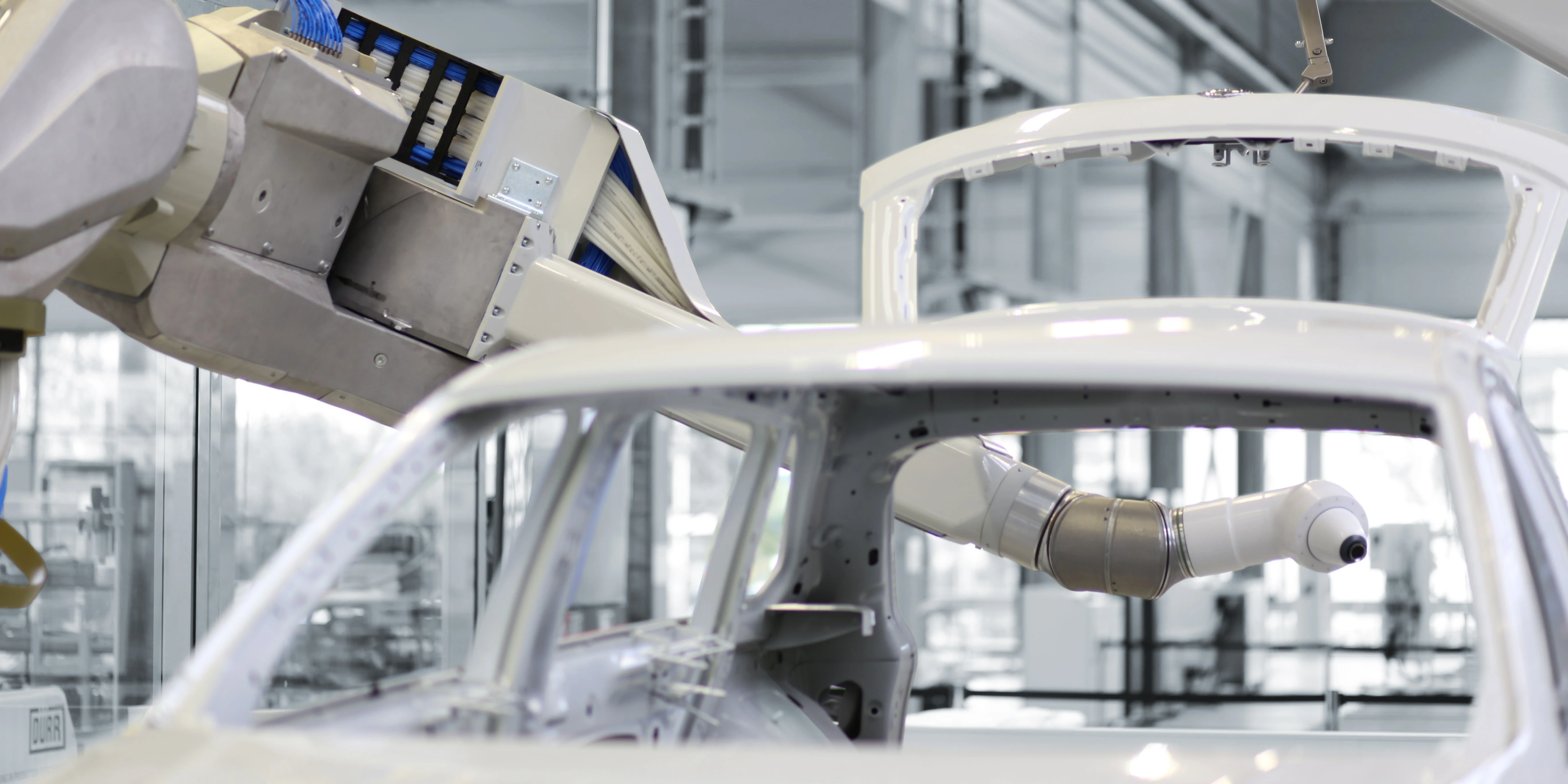

The six-axis variants are still available in the product range, alongside the highly flexible seven-axis robot. Apart from the missing seventh axis, they are identical to the seven-axis robot and are used with or without displacement axis. The → EcoRP E/L133i robots operate either on a top- or bottom-mounted rail. In addition to painting, they also serve as lid openers in interior painting.

Modular robot family

The Dürr robot family benefits from its modular design in production and maintenance. Identical components are supplemented with a few type-specific components. For example, the six- and seven-axis models differ only in the design of lower robot arm 1. This low level of complexity and the uniform component design throughout reduce warehousing costs and simplify maintenance work.

“The outer contours of the new robot generation have been provided with many details to facilitate maintenance and repair in particular. The time required for replacing integrated pneumatic, control-system or high-voltage components in the robot is now up to 50 percent shorter,” says Dr. Schumacher, explaining the innovative design. As an example, the outer shell of the new robot now consists of a few, easily removable cover panels. They are equipped with rapid-action latches for speedy access to the integrated application technology. The color changer and dosing pump are mounted on the robot’s front arm, thereby permitting rapid color changes with little paint loss and low flushing-agent consumption. Hoses are invisibly routed through the robot interior.

New process and movement control system

Dürr’s third-generation robot is controlled by another newly developed product, the → EcoRCMP2 process and movement control system. Much smaller control panels with modular control and drive components, new motors with more power to spare and a digital encoder interface, as well as an integrated safety control system for safe monitoring of the working area and speed, stand for an all-new generation of paint robots based on Dürr’s Smart Factory concept. This control platform combines numerous sensors and actuators belonging to the paint robot and the superordinate maintenance or control systems. An integrated interface makes the robot “cloud ready” and provides all relevant data to meet current and future demands in the Industry 4.0 environment.

Find out more...

... about → EcoRP E043i.