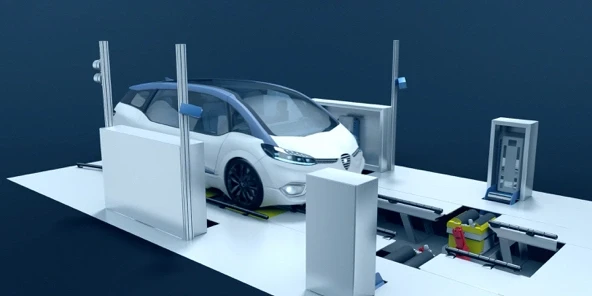

See and drive perfectly with x-light and x-wheel

Nov 13, 2018

Headlamp & wheel geometry alignment with highest precision

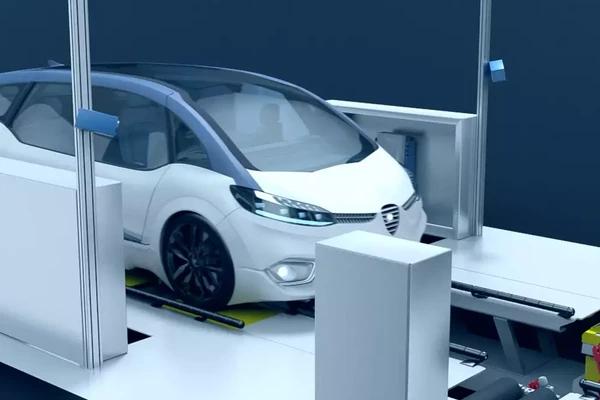

The innovative test beds x-wheel and x-light ensure precise wheel geometry and headlamp setting. Due to the modular system x-wheel, we are able to offer an optimal solution for your requirements in wheel alignment. Tailored to the stringent requirements in the end-of-line area, the x-light setting system enables highly accurate and reproducible test and setting results.

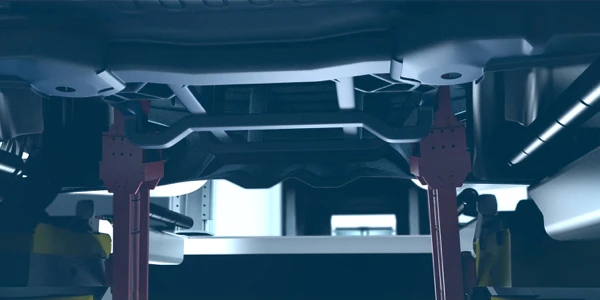

Why does the vehicle geometry have to be set in final assembly?

Relating to a perfectly horizontal steering wheel position when driving straight it is necessary to accurately measure and adjust the wheel geometry in the area of angle minutes. The most important wheel geometry parameters are the individual toe angles, the total toe angles, the camber angles and the castor angles. The individual toe angles of the rare axle determine the driving direction of the vehicle.

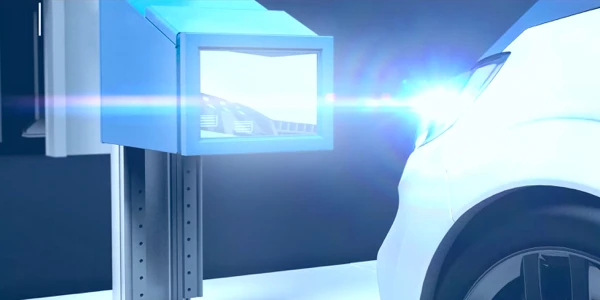

How exactly is x-light used to set headlamps?

With means of specific camera technology, focussing screen, fresnel lens and semi-automatic adjustment tool x-light achieves measurement- and adjustment accuracies better than 0,1% (less than 3,43 angular minutes).

FIND OUT MORE

Dipl.-Ing.

Jörg

Neumann

Director Product Line EoL PVT

Dürr Assembly Products GmbH

Köllner Str. 122 - 128

66346 Püttlingen

Germany

Köllner Str. 122 - 128

66346 Püttlingen

Germany

Dr. rer. nat.

Thomas

Tentrup

Director Development

Dürr Assembly Products GmbH

Köllner Str. 122 - 128

66346 Püttlingen

Germany

Köllner Str. 122 - 128

66346 Püttlingen

Germany