Overspray-free painting at Audi

Dec 17, 2019

Premiere for EcoPaintJet in series production

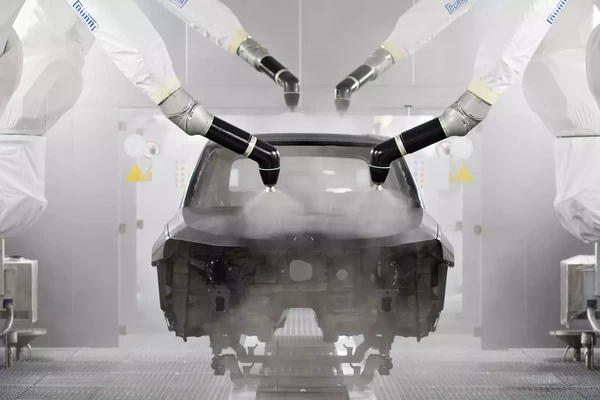

Audi in Ingolstadt is the first car manufacturer to use EcoPaintJet in series production. Contrasting areas can be coated directly in the painting process using this new technology. Paint is applied entirely without overspray, which for the first time allows custom product design to be integrated with automated production in an efficient and eco-friendly process.

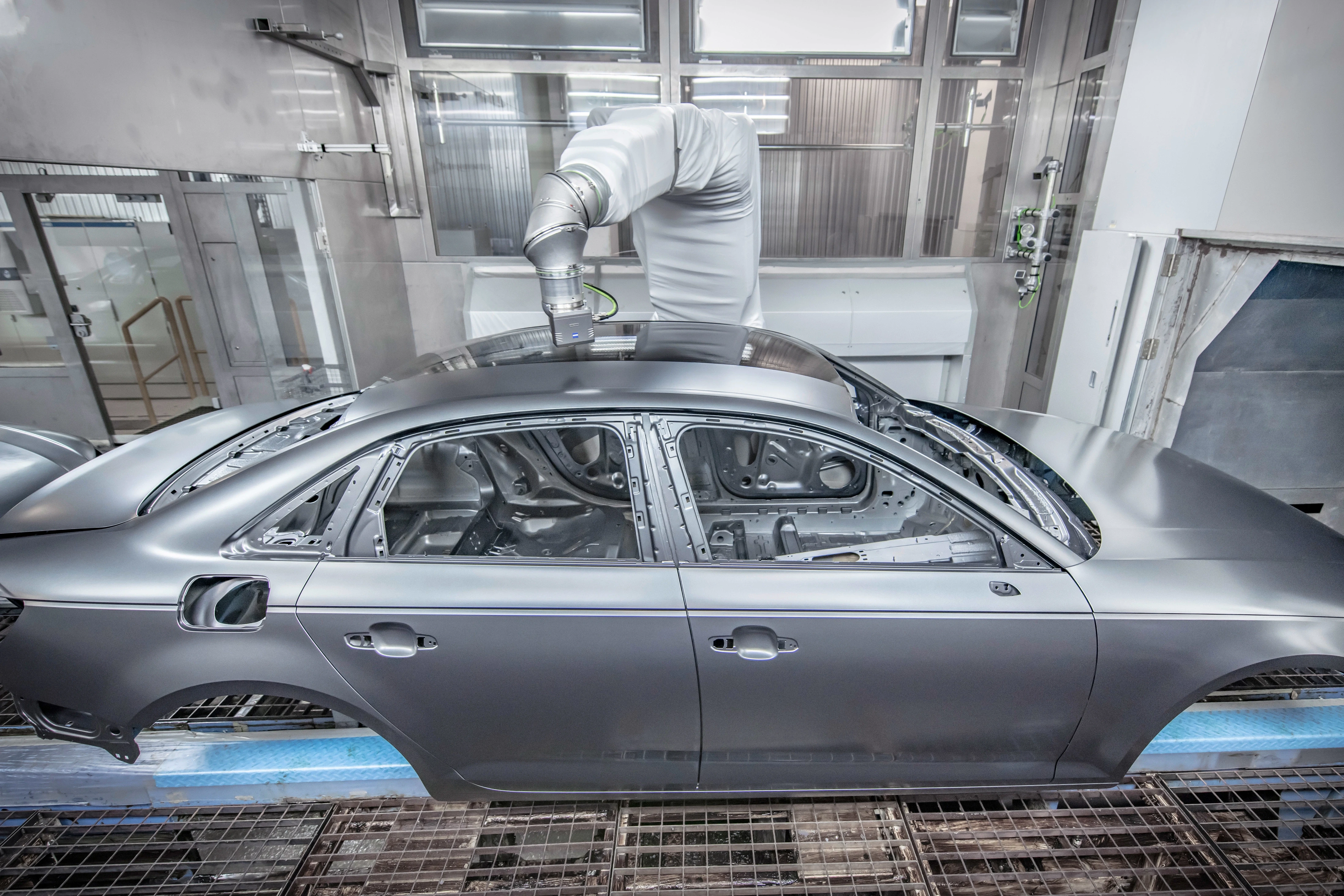

Audi’s “edition one” models of the A4 Sedan and A5 Coupé have been available with a brilliant black roof option since this summer. The carmaker has integrated two-tone contrasting painting into its series production process after thorough testing.

Applying a decorative paint finish previously involved removing the bodies from the painting process, masking and returning them to the painting line. The new application principle revolutionizes this costly and time-consuming method. The contrast roof painting could be integrated into the existing line. The use of this technology eliminates the need for time-consuming masking as well as the need for a second pass through the painting process.

Prior to each painting task, → EcoPaintJet uses a two-stage system to measure the surface to be painted. This determines the body and positioning tolerances, allowing the paint application to be adapted to them fully automatically.

EcoPaintJet then applies paint on the car body in parallel passes with perfect edge definition and no overspray. Operating by itself, EcoPaintJet can paint an area of around 1.8 square meters per minute and can therefore finish a body roof in only 120 seconds. For comparison: Several people have to work for 50 minutes just to apply and remove the masking. Using this high-tech process, Audi can meet customers’ personalization requirements faster and in top quality.

Motivated by energy saving

The paint shop is the main energy consumer in automotive production, accounting for 40 percent of the energy used. In addition to the energy for drying the paint, the energy needed to remove overspray is a major contributor to this high consumption. Even highly advanced technology cannot ensure that all of the sprayed paint actually reaches the vehicle surface. The rest of the paint forms overspray, which has to be separated in the spray booth. Avoiding overspray reduces the air consumption, and this measure alone reduces the energy consumption in a spray booth by 50 to 65 percent.

Overspray-free painting with the EcoPaintJet saves money in production and protects the environment.

More personalization options

The trend toward personalization is another reason in favor of using EcoPaintJet – car buyers are increasingly ordering decorative and contrasting colors to stand out from the crowd. Audi customers can now purchase their cars with a brilliant black roof option.

Eco-friendly and economical

Painting certain body areas in a different color used to require masking the rest of body to protect it from overspray. Masking the body in order to then send it through the painting process again is complicated, reduces production capacity, consumes more energy and produces a lot of waste in the form of masking films and adhesive tapes.