Clever and eco-friendly

Oct 28, 2019

Skoda opens new paint shop in Mlada Boleslav

‘Simply clever’ – this is the slogan Skoda uses to promote its cars. It could also be used to describe the Czech carmaker’s new paint shop. This is because the paint shop, built by Dürr in Mlada Boleslav, is full of clever solutions for sustainable painting.

“Sustainability has top priority at Skoda. We are keeping a close eye on our CO2 footprint”, said the Skoda board member responsible for production, Dr. Michael Oeljeklaus, when speaking to the media at the opening in late August. The carmaker plans to halve the environmental impact of its production by 2025, compared to 2010 levels. One of the products that will help achieve this is the innovative→EcoInCure oven, through which the car bodies will be transported in a transverse rather than longitudinal mode of operation. During this transport, nozzles blow hot air through the windshield opening, thus heating the car body from the inside. This technology reduces the electric energy required for the drying process by 20%. The exhaust air from the oven is purified by an →Ecopure TAR and then reused to heat the oven. Skoda is keeping its eye on the energy consumption levels of the paint shop and on other key figures with the help of MES software, →DXQcontrol (formerly: iTAC.MES.Suite).

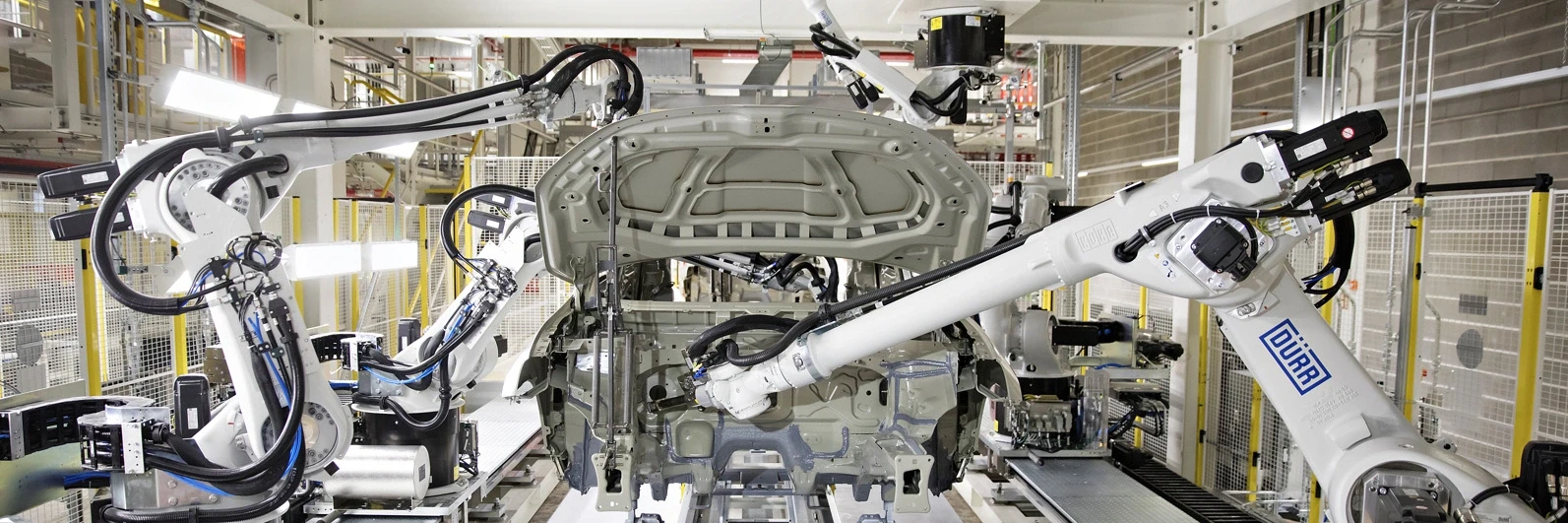

During paint application, the →EcoBell3 high rotation atomizer, →EcoLCC2 color changer and →EcoBellCleaner D2 atomizer cleaner all lower the consumption of paint and solvent. 42 painting robots – thereof 26 from the third-generation – take care of exterior and interior painting, while another 20 robots are in charge of seam sealing. The paint is applied in booths equipped with →EcoDryScrubber technology, which produces up to 80 percent circulating air thanks to dry separation of the overspray and thus saves considerable amounts of energy. The limestone powder saturated with paint from the dry filters serves as desulfurization additive for Skoda´s own power station – the result: no waste. The highly concentrated booth air is purified by an extremely energy-efficient combination of Ecopure®KPR (VOC concentration) and Ecopure®TAR (thermal exhaust-air purification).

The construction of the paint shop in Mlada Boleslav has been one of the largest Dürr projects of recent years in Europe.