Solutions that connect

Oct 22, 2019

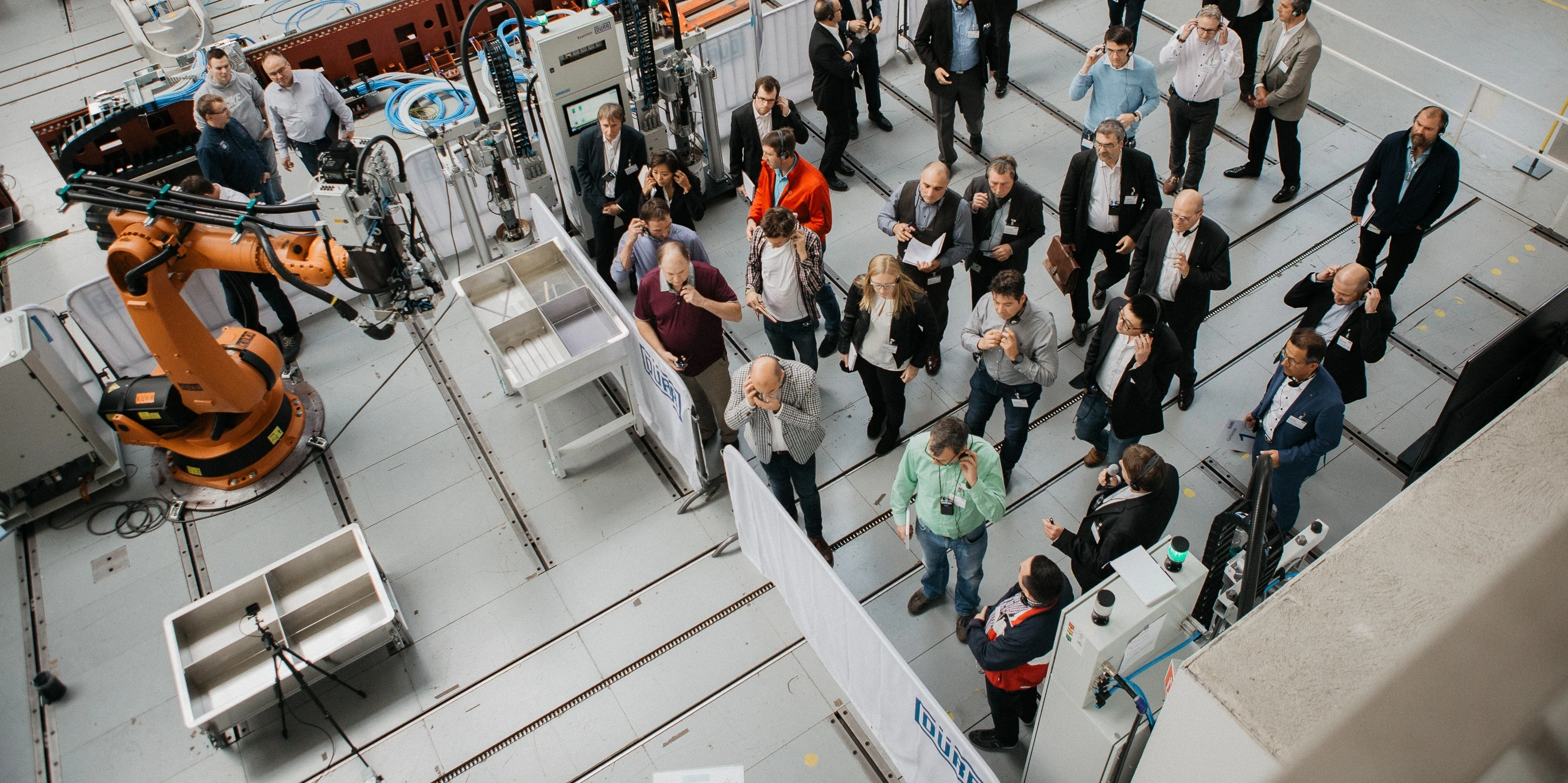

60 attendees from the automotive and Tier 1 supplier industry immerse themselves in the world of gluing

According to the motto “Solutions that connect – Gluing technology for body in white, final assembly and battery production” Dürr’s Gluing Symposium took place on October 10, 2019. The event offered a platform for exchanging ideas about current trends. In addition to live demonstrations, experts from Dürr, Volkswagen, Polytec PT, and Coherix Europe reported on innovative developments and initial practical experiences.

Gluing applications playing an increasingly important role in automotive production. The production of electric vehicle batteries, innovative body concepts with a mix of materials, as well as changed requirements in body-in-white construction and final assembly are posing new challenges. In October 2019, the Gluing Symposium was held at the company's headquarters in Bietigheim-Bissingen, Germany, to focus on gluing, exchange expert knowledge and discuss new technologies.

The symposium focused on new application technology for efficient serial production of battery modules. The complex individual steps involved in production require a wealth of process know-how due to battery modules’ need for protection, cooling, and corrosion-proof sealing. They also need to be able to withstand crashes, and add as little as possible to the overall weight.

“Electric mobility and personalization of vehicles require adapted or even completely new processes in automotive production. Gluing applications play an important role here,” explains Dr. Lars Friedrich, member of the Board of Management of Dürr Systems AG and responsible for the Application Technology Division. “With our technologies, we are contributing efficient solutions that give car manufacturers and suppliers an edge.”

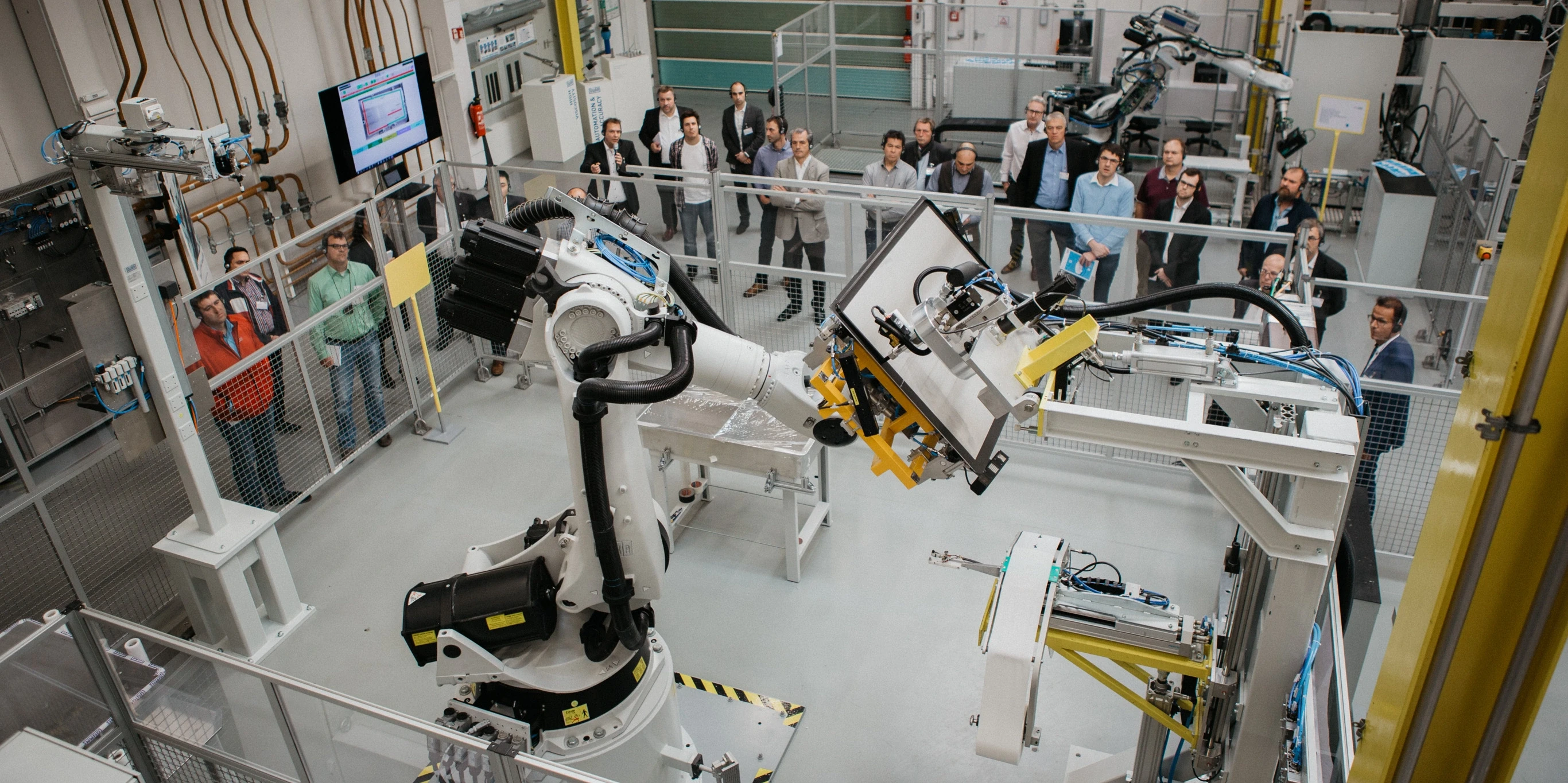

At the Gluing Symposium, the experts presented a complete application technology solution for battery bonding using methods from body-in-white construction and final assembly. In live demonstrations, the participants experienced the bonding of battery covers as well as the automated application of two-component (2K) material for gluing battery cells and filling gaps.

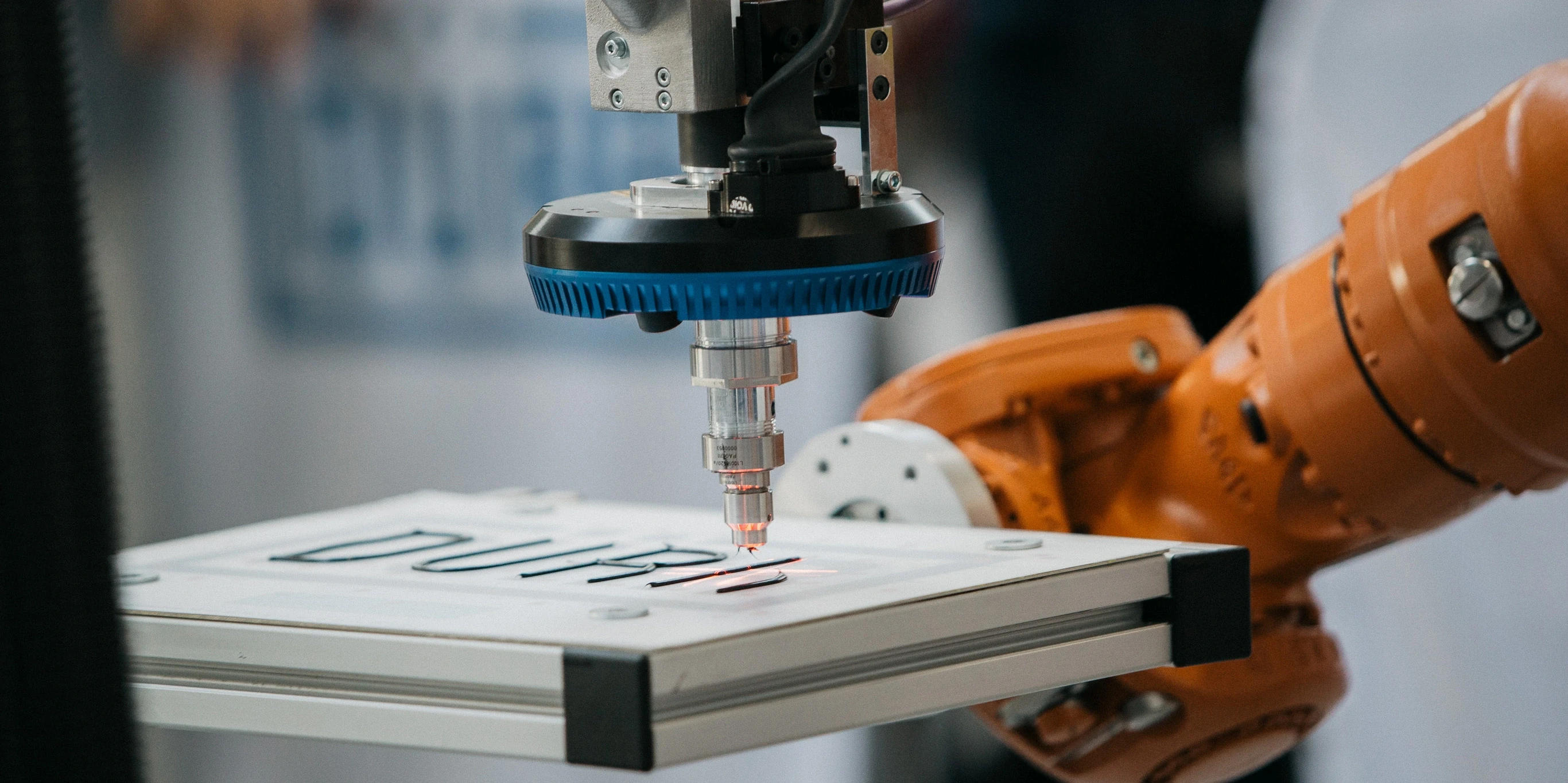

Alongside battery production, the focus was on best cases in body-in-white construction and final assembly. High efficiency is a theme that runs through all process steps. Short bead applications, for example, interrupt the seam and by doing so ensure the quality of the weld spots, save materials, and avoid contamination of the components during the application. This application was also shown in another live demonstration. The visitors had the chance to see the short bead application of the Dürr logo.

In addition, modern methods for 3D inspection and process control as well as new applicators for 1K and 2K adhesives systems were shown. Also on show were speed-sensitive dosing technology for efficient processes as well as innovative thermal management of the highly viscous materials.

Using the example of the side window gluing system used by the VW plant in Zwickau, the attendees were introduced to a fully automated solution in line-tracking operation in final assembly.

The range of topics covered at the event was be rounded off by new digital analysis tools and maintenance software from the → DXQ product family for intelligent control, monitoring, and maintenance of systems.