First AGV for paint shops

Jun 6, 2019

Whether small cars or SUVs, with electric motors or combustion engines, the range of vehicle models being painted in a plant is ever-increasing. Manufacturers want to be able to easily integrate new vehicle types into the production process. With EcoProFleet, Dürr has developed an automated guided vehicle that is precisely tailored to the requirements of a flexible and scalable paint shop.

This desire for flexibility and scalability is pushing linear production to its limits. Flexible automated guided vehicles, or AGVs for short, are an important element in the transition to modular production. Instead of transporting bodies using conveyor technology laid rigidly in the ground, they are moved by AGVs independently and in a parallel formation between workstations and intermediate storage. This eliminates waiting times that previously occurred with different processing times for different car bodies. Downtimes caused by sudden malfunctions are also reduced to a minimum, since AGVs can be redirected to a different workstation.

→ EcoProFleet is the first AGV that has been specifically optimized for the needs of paint shops. That is not only demonstrated by the platform's resistance to paints and solvents. Their low height of 255 mm means that the AGVs can go under all typical workstations in order to drive a car body into a workstation, hand over or pick up bodies, and thus work together perfectly at the interfaces. The integrated technology with laser scanner and safety limit speed guarantees a high level of safety.

EcoProFleet is our enabler for a scalable and flexible paint shop.

Stefano Bell , Product Manager

The concept for energy supply and control is particularly clever. It means that the AGV is ready for operation around the clock – without breaks for charging at the power outlet. This is enabled by supercapacitors as energy storage devices, which charge within just 1.5 minutes. The short time frame while the AGV is handing over or picking up a body is sufficient as loading time for the next section. All the AGVs are therefore always on the move and working. This is guaranteed by a sophisticated control system, which is connected to the central production control technology DXQcontrol. Dürr thus offers a consistent, intelligent control system across all levels for the use of AGVs in paint shops: the device control for physical control of the individual AGVs, the fleet control for route planning and the higher-level order planning are transparently linked via interfaces. This allows EcoProFleet to fully exploit its potential as a flexible and efficient transport system.

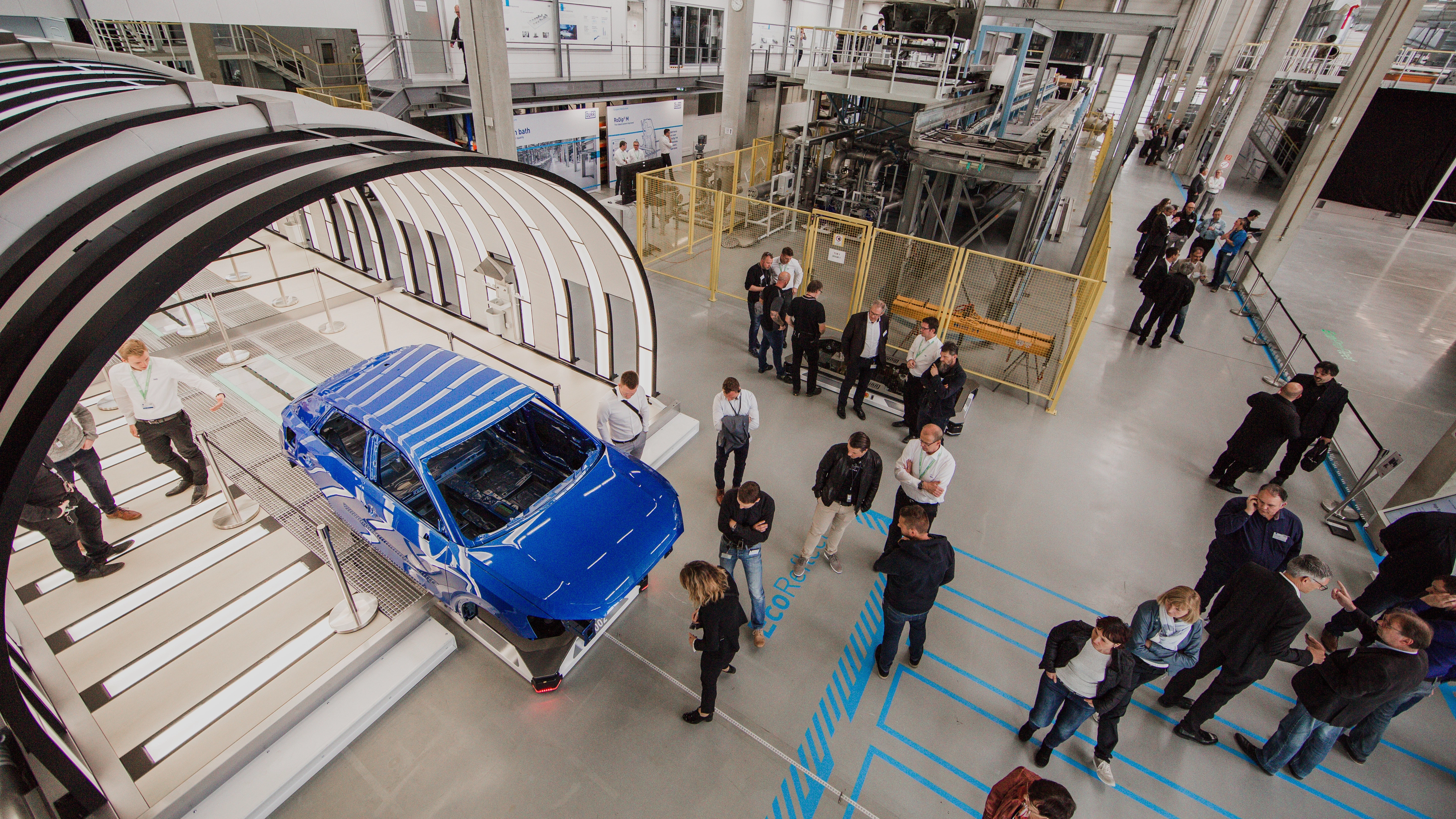

From May 13 to 17, 2019 visitors of the 11th Open House had the chance to see the EcoProFleet handing over and picking up car bodies from several workstations.