Joining forces for the gigafactory

Apr 10, 2024

HOMAG’s subsidiary WEINMANN supplies machines and systems for timber construction. The industrial production of multi-story buildings is playing an increasingly important role in this. Timber houses are climate-friendly, cost-effective, and on trend. When the Swiss start-up Nokera decides to build a gigafactory, WEINMANN is awarded the contract to equip it with facilities. The entire Group pitches in — and leads the project to success together with the customer.

The route to the large factory leads along gravel roads, past fields and sheep pastures. Even the navigation system doesn’t always know its position. The industrial estate on the outskirts of the German city of Magdeburg is constantly growing. Finally, the blue hall appears, 700 meters long and 260 meters wide.

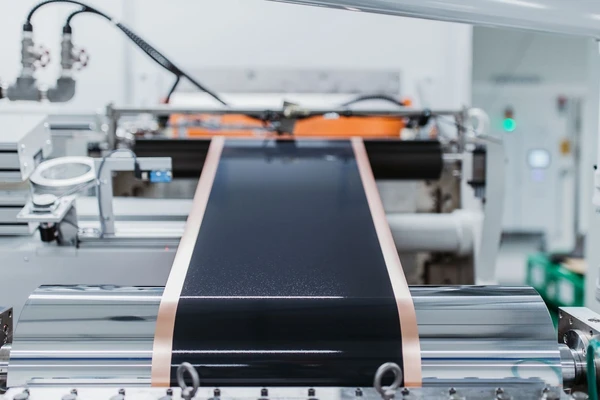

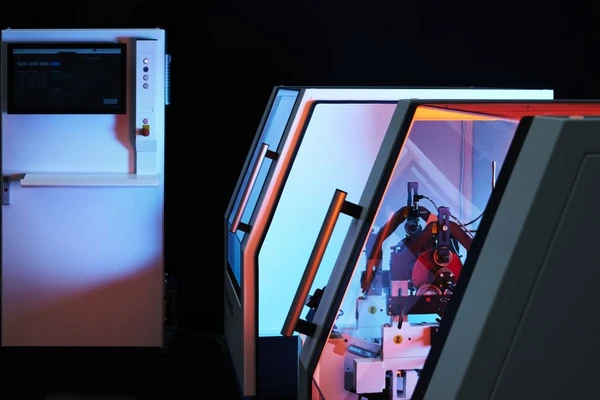

Since 2023, Nokera has been operating the world’s largest factory for prefabricated houses here. It consists of six production lines. Robotic arms dance, and machines saw, drill, or nail so fast that the eyes can barely follow. Before long, the walls and ceilings for more than 20,000 prefabricated residential units made of timber are set to roll off the production line every year. Such quantities are unprecedented in the industry — and the key to the serial construction of cost-effective houses.

The production process is precisely coordinated. First, the framework — the skeleton of a wall, so to speak — is made of individual glued wooden beams. The elements, up to several meters high, are turned automatically, and the cavities are filled with insulating material and sealed. All exterior walls are given a decorative façade. Then everything is loaded and transported to the construction site for assembly.

Catalyst for transformation in the Swabian Alb region

With its modern factory, Nokera has not only set new standards for its own industry. 600 kilometers to the south, the project has also helped WEINMANN in its consistent further development. The HOMAG subsidiary in the Swabian Alb region is the world market leader in timber construction system technology. “We usually supply the prefabricated house industry as well as small and medium-sized carpentry businesses,” says WEINMANN Managing Director Josef Zerle.

In 2020, WEINMANN received an order from Nokera to equip an entire factory with fully automated production lines. Machine equipment for serial house construction was not new territory for WEINMANN. But the scope of the project was.

As a global pioneer, Nokera wanted to manufacture modules for multi-story residential buildings made of timber on a production line in the centrally located city of Magdeburg. “It was clear to us right from the start that we would need assistance,” says Zerle, not least because the WEINMANN workforce was already working at full capacity due to the buoyant construction market at the time. In addition, we were lacking the knowledge and capacity to plan and implement such a large project.

However, the WEINMANN management believed that the project could be realized if several Dürr Group companies combined their strengths. The Group’s top management agreed and gave the go-ahead.

The major effort that followed initiated a transformation of WEINMANN within the Dürr Group. “We said from the outset that this order would showcase the overall competence of the Dürr Group and act as a catalyst for the introduction of new ways of working at WEINMANN,” says Zerle. The experience gained from this large-scale order will pay off, as there are strong indications that further major orders of this kind will follow.

Timber construction is on trend

The proportion of housing built with timber has been growing for years. Around one in four new single-family homes in Germany is already built using this sustainable raw material. The share of multi-story buildings made of timber has almost doubled compared to 2020.

Prefabrication in series is sustainable — not only economically, but also ecologically, as wood stores climate-damaging CO2 for a long period of time. It also offers solutions for the global shortage of skilled workers. Until now, most buildings have been constructed on site by hand. This costs working time and a lot of money. The factory produces timber buildings more efficiently and with consistently high quality.

Another growth driver for timber construction is the energy-efficient renovation of buildings. “Instead of gluing polystyrene panels to the house, it makes sense to use a mass-produced ecological wooden façade,” explains Zerle. These insulating elements, too, are already being produced using WEINMANN systems.

2020

Planning contract for the systems in the gigafactory awarded to WEINMANN

2021

Supply contract awarded to WEINMANN and start of implementation

2022

Start of assembly of the machines and systems

2023

Launch of production at the gigafactory near Magdeburg

We said from the outset that this order would be a catalyst for the introduction of new ways of working at WEINMANN.

Josef Zerle, Managing Director of WEINMANN

Residential construction needs a breath of fresh air

The market for new housing is facing major challenges. Professor Michael Voigtländer, an economist at the German Economic Institute (IW) in Cologne, believes that serial construction is an important approach to solving these issues.

Supply and demand are currently mismatched in the residential construction sector. While solvency has declined due to higher interest rates, construction costs continue to rise due to material and labor costs as well as increased requirements. In the last three years alone, the costs of new construction in Germany have risen by approximately 40 percent. As a result of this combination, the number of building permits has fallen sharply. The situation in Germany is particularly precarious because construction activity is declining while the population is growing rapidly. With 1.46 million people, Germany saw record immigration in 2022; in Berlin alone, the population grew by 80,000 people in one year. One reason for the strong influx is the large number of refugees from Ukraine, but the immigration of skilled workers has also picked up again. However, Germany is not the only country facing problems from rising interest rates and higher construction costs; building permits have also plummeted, at least temporarily, in many other European countries and in the US. Ultimately, the challenges are very similar across the industrialized countries.

If interest rates start to fall slightly again as a result of declining inflation rates, this could provide new momentum for construction activity. But this is where the next challenge arises: Skilled labor is in extremely short supply and rising wages are leading to further cost increases. Among the ten occupations in Germany with the greatest shortage of skilled workers, two are in the construction sector: construction electricians and heating installers. In addition, housing construction will have to focus more than ever on sustainability, both in the construction of properties and in their management. The building sector accounts for around 36 percent of carbon dioxide emissions through hot water processing and air conditioning alone.

In view of these challenges, innovative solutions are required that significantly increase the productivity of residential construction. Serial construction can be a decisive approach here. In this method, residential buildings are no longer just erected on construction sites, but are partially prefabricated in factories. This means housing can be built faster, at lower cost, and with fewer workers.

No blueprint

While WEINMANN had not been geared toward realizing such large-scale projects up to that point, it was nothing unusual for the parent company. For decades, Dürr has been planning and building paint shops for automotive manufacturers all over the world. Their order value can easily exceed 200 million euros. The Group’s subsidiary HOMAG has the knowledge and experience to handle large orders for the furniture industry.

The Dürr Group then had to transfer this knowledge to timber construction, because there was no blueprint for the order from Nokera. In the first three months, the Group’s own consulting companies SCHULER and Dürr Consulting were instructed with the initial planning to determine what a gigafactory should look like and how production should take place. “We also had to clarify how the individual stations could be automated and interlinked,” says Jürgen Dörfeldt, who managed the overall project. He has already handled many major orders in Dürr’s paint systems business.

At WEINMANN, the experts considered how they could combine their machines and systems for the high outputs of large production lines. Meanwhile, HOMAG took care of procurement. Not an easy task. A project of this size requires huge quantities of steel, cables, robots, control cabinets, and much more to be in the right place at the right time.

95%

of Nokera’s building materials can be recycled.

In just

3 months

Nokera can erect residential buildings thanks to serial construction.

Source: Nokera

We were faced with serious supply bottlenecks. We countered this with a systematic approach and the consistent dedication of everyone involved.

Jürgen Dörfeldt, Senior Executive Project Director at Dürr

Fighting supply bottlenecks

This was only possible with meticulous planning and a lot of experience. Especially in a difficult environment, affected by the coronavirus pandemic and the war in Ukraine. “We had to deal with severe supply bottlenecks, which we countered with a systematic approach, regular consultations, and the consistent commitment of everyone involved,” says Jürgen Dörfeldt. The clear and stringent project management was fundamental to the success. “That is why it always worked,” says the project manager.

Another challenge was WEINMANN’s limited production capacity. In order to produce that many machines in the specified time, several Group locations had to help out. The HOMAG plants in Schopfloch, Lichtenberg (Saxony), and Środa Wielkopolska (Poland) stepped in, as did Dürr Poland in Radom. The automation specialist Teamtechnik was also involved with technical personnel and its plant near Stuttgart.

In July 2022, assembly of the machines and systems began. Here, too, the scale of this extraordinary project was evident. The processes on the construction site had to be organized and deadlines had to be strictly adhered to. This also applied to the agreements with the customer and the suppliers.

At the end of 2023, the factory went into operation. Initially on a trial basis, because before series production begins and transitions into the ramp-up phase, the employees are trained by the WEINMANN Academy to deliver outstanding performance. But you can already admire what the result will look like. Nokera has built a four-story show house right next door. With an unobstructed view of the gigafactory.

More about

- Technology for affordable housing: The → gold rush in timber house construction in North America

- Website of the Swiss start-up company → Nokera

Alisa

Finkbeiner

Global Product Marketing

WEINMANN Holzbausystemtechnik GmbH

Forchenstr. 50

72813 St. Johann

Germany

Forchenstr. 50

72813 St. Johann

Germany