Bietigheim-Bissingen, July 10, 2020 – Dürr presents a completely new layout for automotive painting. Instead of the conventional painting lines, in which cars are painted one after the other, the paint shop of the future will, for the first time, work with painting boxes standing side by side. As a result, the automotive industry can paint a large number of different models with high flexibility and – depending on size – at different speeds. For the transport of car bodies to the boxes, Dürr has developed the world’s first driverless transport system especially for paint shops. The paint shop of the future saves time and material, is more sustainable and can be easily expanded. This also makes it suitable for new e-mobility start-ups that start with small quantities and later expand production.

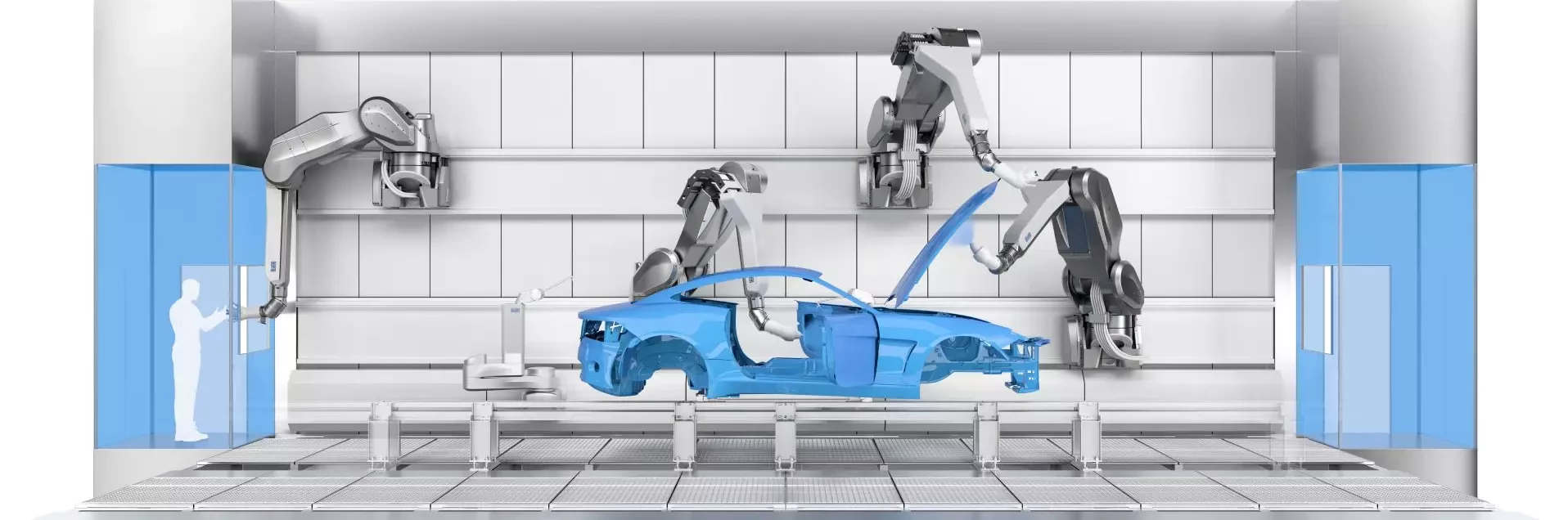

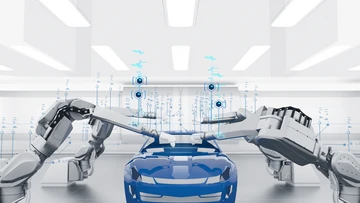

In Dürr’s new layout, there are adjacent boxes, i.e. paint booths, in which robots apply the paint. In each box, the painting time is precisely adapted to the requirements of the respective body. This means that smaller vehicle models can be painted faster in one box and thus in higher quantities, while in another booth longer cycle times are used for larger cars.

New models can be integrated into the existing system more easily and quickly than before. While one box is being adapted for a new electric vehicle, for example, production can continue as planned in the remaining booths. Another advantage: For maintenance or in case of malfunctions, it is no longer necessary to stop the complete painting line, but only the work in the affected box. The other boxes remain in operation and can be used as an alternative. It is also possible to react more flexibly to the under-utilization of a paint shop. The box concept also allows additional capacities to be added with little effort in order to produce higher quantities.

Interior and exterior areas are painted in one box

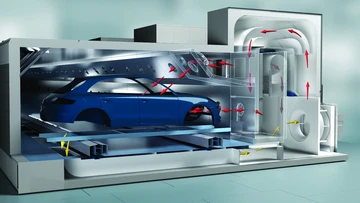

The paint shop of the future offers further advantages thanks to its new EcoProBooth paint booth, for which Dürr has filed a patent application: It is used to paint both the exterior and interior parts of the bodies. Previously, two different paint booths were required for this purpose, and conveyor technology was also needed to transport the bodywork between the booths. The exterior and interior painting in one booth saves time. Paint losses during color changes can even be reduced by up to ten percent compared to line production if only one color is applied in a particular box – for example white, the color of currently around 30 percent of all cars produced. Fewer color changes also mean less color loss as well as less rinsing and cleaning processes and thus also fewer emissions of volatile organic compounds, so-called VOCs. Since paints have different drying times, the box concept offers the flexibility to adjust the cycle times for this aspect as well.

A special feature of EcoProBooth: So-called service cubicles for the maintenance of the painting robots are integrated in each corner of the paint booth. These service cubicles are continuously flushed with fresh air and can be entered at any time, even without protective breathing equipment. This is not possible in conventional booths. If a robot in the EcoProBooth needs to be cleaned or maintained, it moves to the service cubicle and stretches its arm with the paint atomizer through a connecting window into the service area, where a worker can easily reach it. This saves time and thus significantly increases system availability.

Driverless conveyor technology

Additional flexibility in the paint shop of the future will be provided by a high-bay warehouse that serves as an intermediate storage area for the car bodies, and freely controllable, driverless transport systems. Instead of rigid conveyor technology on rails, these so-called AGVs (Automated Guided Vehicles) transport the cars from one work station to the next in a pre-sorted and precise manner. The AGVs are controlled by intelligent Dürr software, thus ensuring an efficient utilization of all painting boxes. With EcoProFleet, Dürr has developed the first AGV designed especially for paint shops.

Dürr is the only manufacturer to offer such a flexible painting concept without rigid lines. “We are thus underlining our innovation leadership and making use of our expert knowledge of production processes”, says Ralf W. Dieter, CEO of Dürr AG.

“With our layout for the paint shop of the future, we are taking a pioneering role”, says Dr. Jochen Weyrauch, Deputy CEO and responsible for the automotive business on the Board of Management. “We thus support both established manufacturers and start-ups with their new installations: They can all produce flexibly – no matter what the next decades hold in store.”

On the one hand, the paint shop of the future is suitable for car manufacturers with many different vehicles who want to easily integrate new models into their production processes. On the other hand, it is also attractive for electric vehicle manufacturers who are new to the market and initially produce small quantities but want the option of rapidly expanding the system.