“Flexibility, cost efficiency, and sustainability are the most important demands that manufacturers are placing on the painting process today. We meet these demands through our concept of the paint shop of the future,” explains Dr. Jochen Weyrauch, Deputy CEO of Dürr AG—responsible for the paint systems and final assembly business and CEO of Dürr AG as from January 1, 2022.

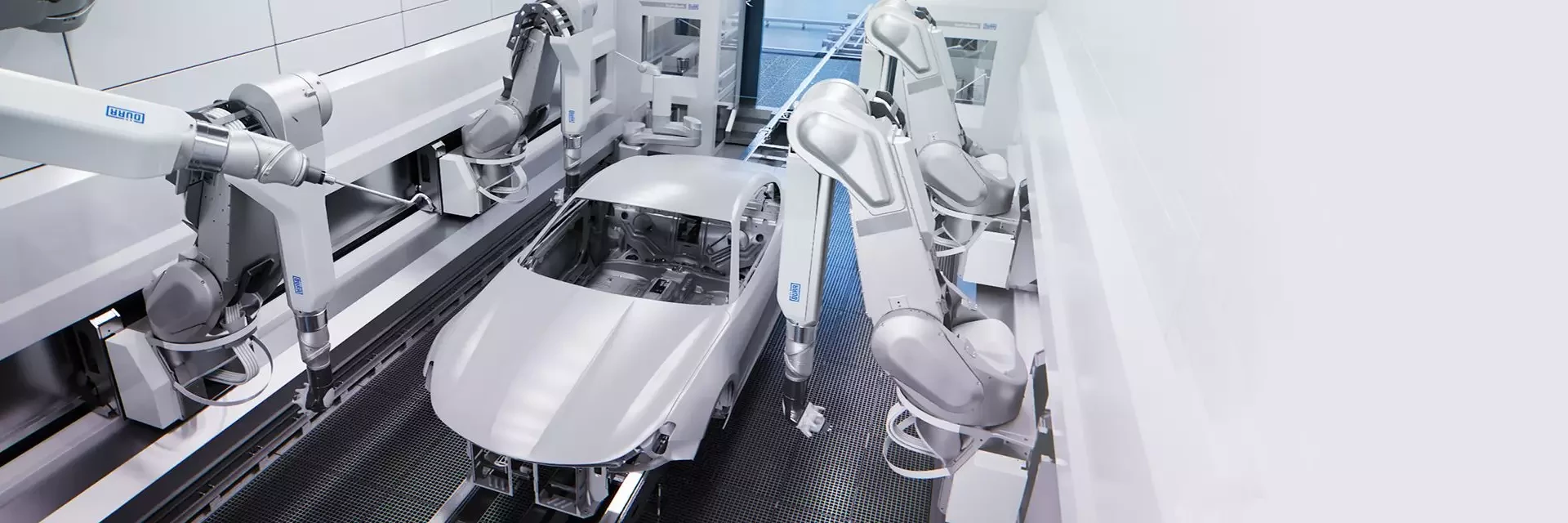

Based on this concept, the roughly 120 work stages in an automotive paint shop take place in stations or smaller sections—in parallel and accurately timed for the requirements of the individual car body. The adaptable layout makes it easy to expand capacities and enables manufacturers to send a greater number of vehicle types through the painting process—ideally, even individual items can be handled while production is underway.

Intelligent flexibility

Automated guided vehicles (AGVs) are used to supply the individual stations with car bodies at the right time. Dürr’s EcoProFleet is the first AGV specially developed for paint shops and can be seen in action at the Open House.

Dürr will present a new, modular system design for pretreatment, where car bodies have dirt particles removed and receive their anti-corrosive coating. The design is based on standardized chambers instead of dip tanks that are arranged one after the other. This is not only more flexible but also saves a lot of space.

For the painting process itself, Dürr will present its patent-pending EcoProBooth paint booth. It is used for painting both exterior and interior surfaces of cars. Until now, this has required two different booths between which the car bodies have had to be transported using conveyor technology.

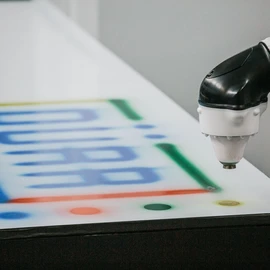

Dürr has further developed its system for the two-tone painting of car bodies. Aside from saving carmakers time and energy, it also generates less waste. In this painting process, a robot applies the contrasting or accent color so accurately that no overspray is generated. This dispenses with the time-consuming process of masking the other car body areas. Thanks to the further development of the EcoPaintJet Pro, not only is it possible to apply the two-tone lines to car body roofs, which is on trend right now; the system also allows for vertical areas to be painted and for decorative colors to be applied.

The new EcoBell4 ensures maximum quality. It applies paint accurately, using an even spray jet. Due to its faster color change times, it enables more cars to be painted in the same amount of time. Another big plus: The low consumption of paint and solvents lowers the emission of volatile organic compounds (VOCs)—another contribution toward sustainable production.

Artificial intelligence for greater quality

Dürr’s digital products ensure that the individual production stages are integrated smoothly. One example is the DXQplant.analytics software. It uses artificial intelligence (AI) to analyze data from the painting process. This helps staff responsible for quality assurance to identify any connected issues at an early stage and prevent faults. Its feedback function enables continuous ‘learning’ of the AI algorithm. This makes predictions, for example on maintenance requirements and quality, increasingly accurate.