Smart up your testing efficiency

Dec 19, 2019

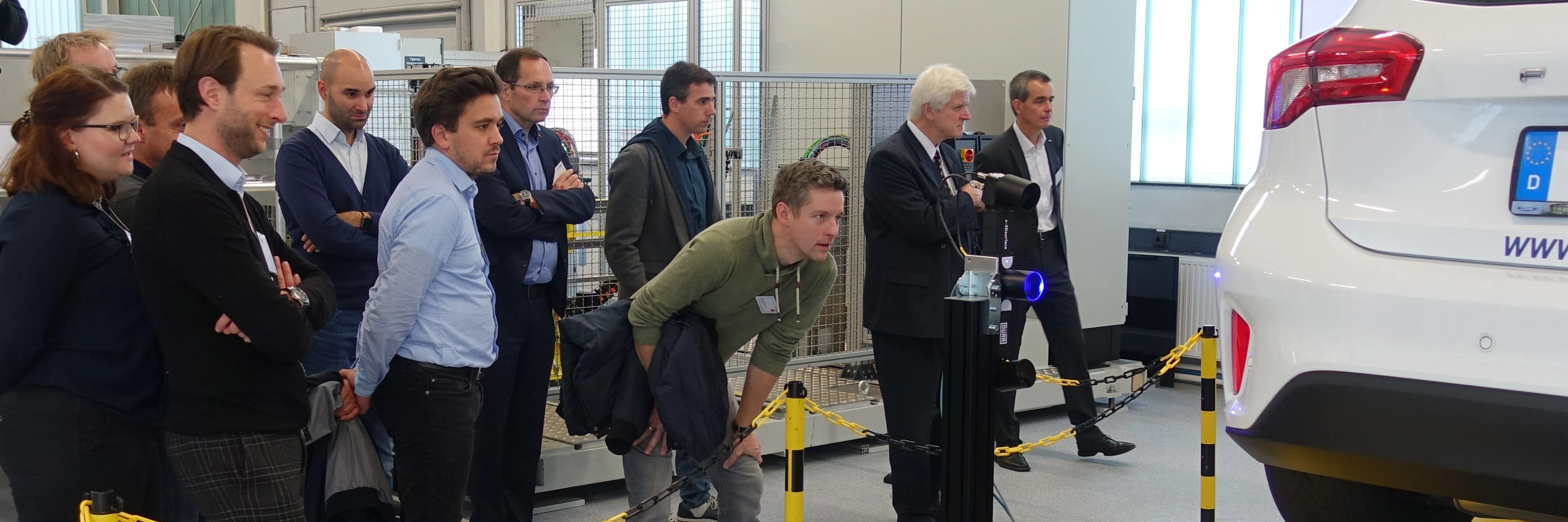

New measuring and setting technology pulls in the crowds at the customer day

Dürr Assembly Products presented new sensors in measurement and setting technology at the End of Line as part of a customer day. These innovations measure with a high degree of precision and ensure great flexibility with regard to new measurement tasks. Over 40 customers and partners of big-name automotive manufacturers convinced themselves of Dürr’s power of innovation at the product launch.

Several products were presented together at this year’s Customer Day on November 26 and 27, 2019, in the Saarland (Germany). The participants were able to experience further developments and product innovations in live demonstrations.

The → multi-portal system x-align from Dürr Assembly Products optimizes the precise setting of the rear axle during module pre-assembly. Product variety, production efficiency and ease of maintenance are improved in this way. Two platform-specific central lifters perform the sequence-controlled setting process – the result is reduced plant complexity and greater flexibility when changing a product to future axle variations.

With x-LinCheck-3D, Dürr Assembly Products presented a calibration system that ensures the accuracy and reliability of the installed test and measurement equipment during operation. The probe does not have to be removed from the system as previously required. Directly in the wheel alignment stand the mobile x-LinCheck-3D measures the linearity of the sensors in the entire measurement volume and supplies the results in real time.

Continuous expansion of the service is pursued at Dürr to the same degree as technological enhancement. With x-aguide, the customer is provided with a Smart Service Tablet that supplies important information and manuals on products in real time and presents it by means of Augmented Reality. Moreover, the tablet can be used to contact a specialist for immediate assistance via video call. This simplifies and shortens service tasks enormously.

The highlight of the Customer Day was the presentation of the innovative → x-3Dsurface, a flexible sensor that measures chassis geometries with maximum precision. This further development of existing measurement technology is based on a contactless sensor. x-3Dsurface can be easily integrated into existing Dürr systems. It works on the basis of stereophotogrammetry. By measuring the entire side surface of the wheel as well as the wheel arch edge, a "measuring surface in space" is created. The height measurement is reliable, even for complicated fender geometries. Additional hardware is not needed.

The precisely stable and all-time reproducible measurement with structured LED light is also independent of the car body shape and tire geometry. Individual measuring ranges can be defined as required. All these factors contribute to a unique level of flexibility being achieved in the area of measuring and testing.

Customer days are always a valuable opportunity for Dürr to enter into direct exchange with customers and partners and obtain immediate feedback. The presentation of the new technologies and in particular the x-3Dsurface conveyed a strong and lasting impression of Dürr Assembly Products’ power of innovation. The Dürr Group subsidiary is thus further consolidating its position as the technology leader for measuring and adjustment tasks.