Wood is digital

Feb 1, 2019

tapio: the world’s first digital marketplace for the woodworking industry

With the launch of “tapio” the HOMAG Group has become the first mechanical engineering company in the world to offer a digital marketplace for the woodworking industry.

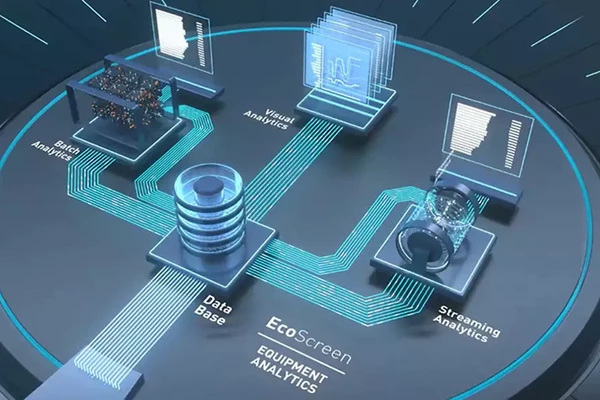

→ tapio is an open system, which means that tapio’s business partners – manufacturers of machinery, tools and materials – are able to use the tapio technology platform to offer their services and digital solutions to anyone operating in the woodworking industry. As a result, individual business processes in woodworking can be made more efficient, faster and more reliable.

The digital marketplace launched by Dürr subsidiary HOMAG provides all required information on production as well as on the machinery, tools and materials used. This assures furniture manufacturers and other companies operating in the woodworking industry of maximum transparency. In fact, → tapio allows customers to derive optimization measures for their production.

For example, a glance at the MachineBoard displayed on a tablet or smartphone shows whether the equipment is performing according to plan along the entire production process. Push notifications will alert a machine operator the moment an intervention is needed. Maintenance measures can also be planned in advance (predictive maintenance), and urgent service requests can be created directly and forwarded to the right service partner.

Less waste

Another useful feature is the live video transmission in the ServiceBoard, which is designed to help overcome language and distance barriers. The intelliDivide of the HOMAG Group allows the sawing process to be optimized, for example, with the aim of reducing waste as well as time required.

Another advantage is that the anonymized customer data is constantly saved in → tapio and can be retrieved at any time, and there is no risk of data being lost. The DataSave feature even saves machinery configuration data automatically, ensuring that in the event of a machinery breakdown, the data can easily be restored.

All new machines offered by HOMAG are “tapio”-ready and can quickly and easily be connected to → tapio, without incurring additional costs. Featuring state-of-the-art security technology, HOMAG’s digital marketplace complies with the most stringent data protection requirements.

Christian Neumann, general manager of tapio: “Our digital marketplace has enabled us to prepare the ground on which a variety of digital solutions for customers will be able to grow and prosper.”

Our digital marketplace has enabled us to prepare the ground on which a variety of digital solutions for customers will be able to grow and prosper.

Christian Neumann, general manager of tapio

Find out more...

... about → tapio.