Maximum transparency, maximum information

Feb 8, 2019

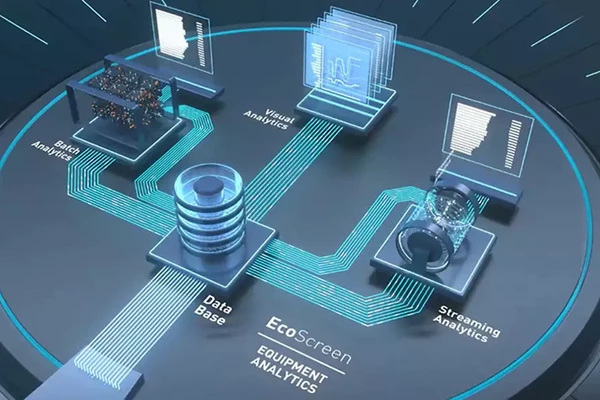

Plant visualization with DXQequipment.operation

The right data always at your fingertips – DXQequipment.operation (formerly EcoScreen Web) delivers process and production data in real time, both to the office PC and to a mobile device at the paint shop on site. Dürr's web-based visualization solution sets a new standard on the road to Industry 4.0. The user-friendly software offers customers maximum information transparency.

Producing vehicles is becoming ever more complex. In parallel, the intelligent connectivity of machines and systems is combined with modern sensor technology to offer a substantial efficiency potential. But the large volume of data can only be used effectively if information is available to the right person at the right time and the right place.

A smart solution that makes this possible is → DXQequipment.operation. This newly developed software program is the result of many years of Dürr's experience in plant engineering and its great expertise in Industry 4.0. DXQequipment.operation is browser-independent and touch-optimized, making it the logical progression of the previous visualization platform, EMOS.Web. Both new and existing plants become HTML5-compatible with DXQequipment.operation. Thanks to its upgrade capability, Dürr offers investment protection on the journey into the digital age. The Dürr support team is, of course, available 24/7 to provide assistance with every aspect.

DXQequipment.operation covers all areas of a paint shop. However diverse these may be, the software ensures uniform and clear visualization, thus making it especially user-friendly and easy to handle.

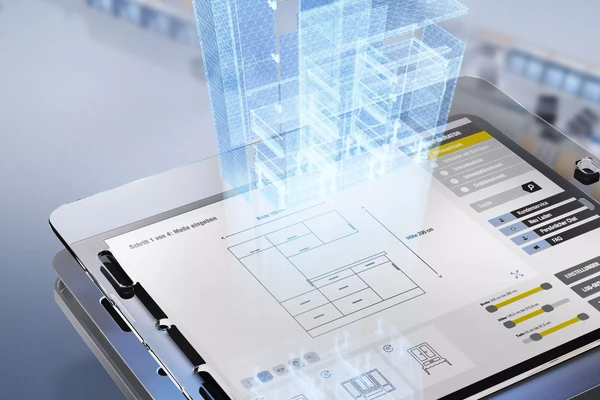

For use at the plant and on mobile devices

What's more, the application design is touch-optimized, replacing the mouse click with a light touch. → DXQequipment.operation works not only on permanently installed screens directly on the machines but also on mobile devices: Whether on the Dürr DXQpad (formerly EcoPad) tablet or on other mobile devices – plant control is flexible and can be performed directly on site or in the production building. Conversely, the information can be accessed from any authorized workstation, with user rights being verified automatically. User groups and rights do not have to be managed twice, since the system can be fully integrated into carmakers' existing IT landscapes.

Transparent, secure and smart

With → DXQequipment.operation, Dürr has reached a new digital milestone. Based on state-of-the-art technology and an intuitive user concept, a simple connection is created between man and machine – for maximum information transparency in Industry 4.0.

Your benefits

# Integration of mobile devices

# Plant-wide visualization

# Browser independent access

# Touch-optimized design

# Highly available system infrastructure