Electrifying contacts

Mar 23, 2023

The energy crisis is enabling a comeback for the European solar industry. Good for companies such as Teamtechnik. The Dürr subsidiary builds machines that interconnect individual solar cells at lightning speed so they can be put together to create large modules.

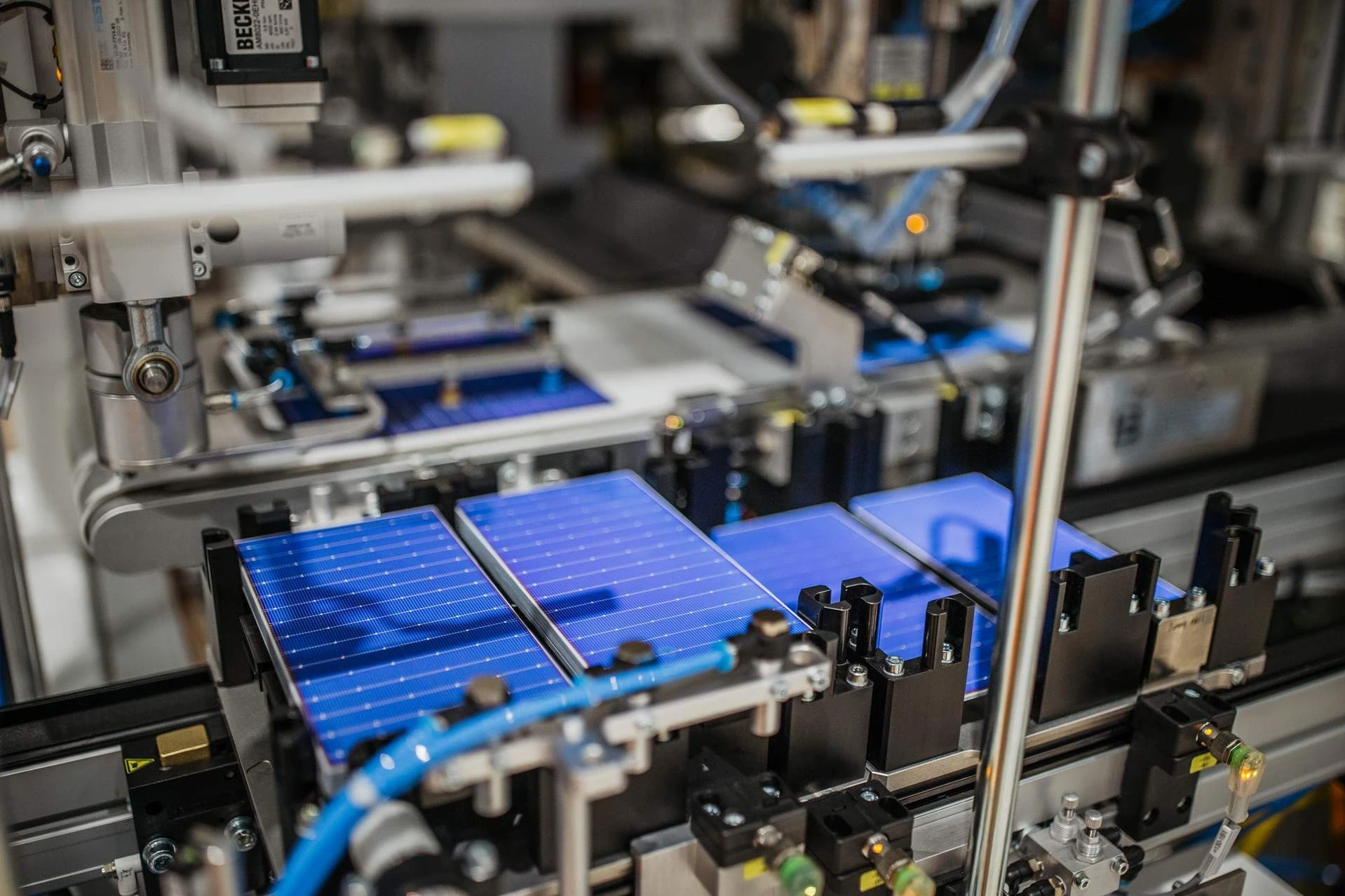

Metal frames are gliding on conveyor rails, lights are flashing, and vacuum grippers are dancing in a uniform rhythm. A layperson would scarcely notice what tasks are being completed by these complex machines, built by Teamtechnik in the German town of Freiberg am Neckar. Only the solar cells, stacked in the factory building for demonstration purposes, indicate what type of sector the buyers come from.

The Dürr subsidiary produces specialized machines for the solar industry. These so-called stringers interconnect individual solar cells. The strings thus created are later assembled to produce complete modules and can eventually be found in photovoltaic systems on roofs and on open land. “Since solar modules are needed in large quantities, production must be fast and highly automated,” says Thomas Fischer, Head of Mechanical Design & Technology Development.

The machines built by Teamtechnik help to meet the rapidly growing demand for solar technology, since photovoltaics, along with wind power, are crucial in achieving climate targets. In addition, solar power can be harnessed more and more cost-effectively. This is partly why global generating capacities increased tenfold between 2012 and 2022. The sector anticipates a further increase, with figures expected to double by 2025.

We knew that this was right up our street.

Stefan Roßkopf, CEO Teamtechnik

Energizing connections

During a tour of the manufacturing facility, Fischer explains how the machines work. “The stringer places the fragile solar cells next to each other. These are then connected in series, with a copper wire placed onto them and soldered to the silver contacts located on each cell.” In the finished solar module, this connection enables the outflow of electricity harnessed from sunlight. This production stage poses a challenge: It must be completed quickly yet accurately and reliably. That’s no problem for Teamtechnik. Even though the positioning of wire and cells needs to be accurate to within a fraction of a millimeter, the systems are run with cycle times of under two seconds.

What gave the company the idea to manufacture stringers? The beginnings date back more than two decades, according to CEO Stefan Roßkopf. At the time, the automation specialist was looking for new business ideas. In the years after its foundation, Teamtechnik was mainly building individual, special systems tailored to customers’ needs. Now, the plan was to add more standard machines — these would be produced in large quantities for a wide customer base and make the resources linked to each order more straightforward. “That’s why we sounded out various markets in the early 2000s,” says Roßkopf.

The promising market of renewable energy attracted the interest of Teamtechnik’s technology scouts. When looking at the production of solar modules, they were baffled: In numerous factories, hundreds of employees were still soldering solar cells manually in order to connect them.

The Teamtechnik management decided to find a simpler and quicker way. It was actually an obvious idea — which nobody had consistently pursued up until then. “We knew that this was right up our street,” says Roßkopf. A team of developers got to work.

A successful business idea

In 2005, Teamtechnik launched the first stringer. Two years later, the company was able to produce the machines in series. It was especially the growing Chinese solar industry that was keen to get its hands on the technology from Freiberg am Neckar. “In 2011, we were world market leader,” says Roßkopf. Back then, five machines would leave the company each week. Stringers made up around 60 percent of Teamtechnik’s sales.

Then, competitors in Asia started building these specialized machines themselves, while in Europe government incentives for the solar industry were being reduced. Even though sales of stringers declined, Teamtechnik was not discouraged and continued this business on a small scale.

Since then, a new generation of solar cells has come onto the market. The cells generate more electricity per square meter, with the downside that they cannot tolerate the 200 degrees Celsius necessary for soldering. Together with the Fraunhofer Institute for Solar Energy Systems ISE, the Teamtechnik experts have found a way to connect solar cells using an electrically conductive adhesive. Now, in simple terms, new machines apply the adhesive in exactly the right places with the help of a fine-mesh screen.

The solar industry comeback

This kind of innovation is well received. Around 20 of the new machines are going to a customer who is putting a solar module factory into operation in Italy in 2023. Next year there is the possibility of more large orders. Roßkopf is optimistic. “The Western solar industry is on the rise again.”

This has several reasons. For one thing, the oil and gas shortages are creating a new tailwind for the solar industry. In addition, companies are seeking to become independent of suppliers from other parts of the world. Furthermore, the United States is currently pumping billions of dollars into the renewable energy sector to fight inflation and boost its economy.

Roßkopf reckons that the shift in the energy world will continue to have a positive effect on Teamtechnik’s business. This is because Teamtechnik also manufactures assembly and test systems for batteries, which are used, for instance, in electric vehicles and home energy storage. This means the company is involved in important points of tomorrow’s energy system.

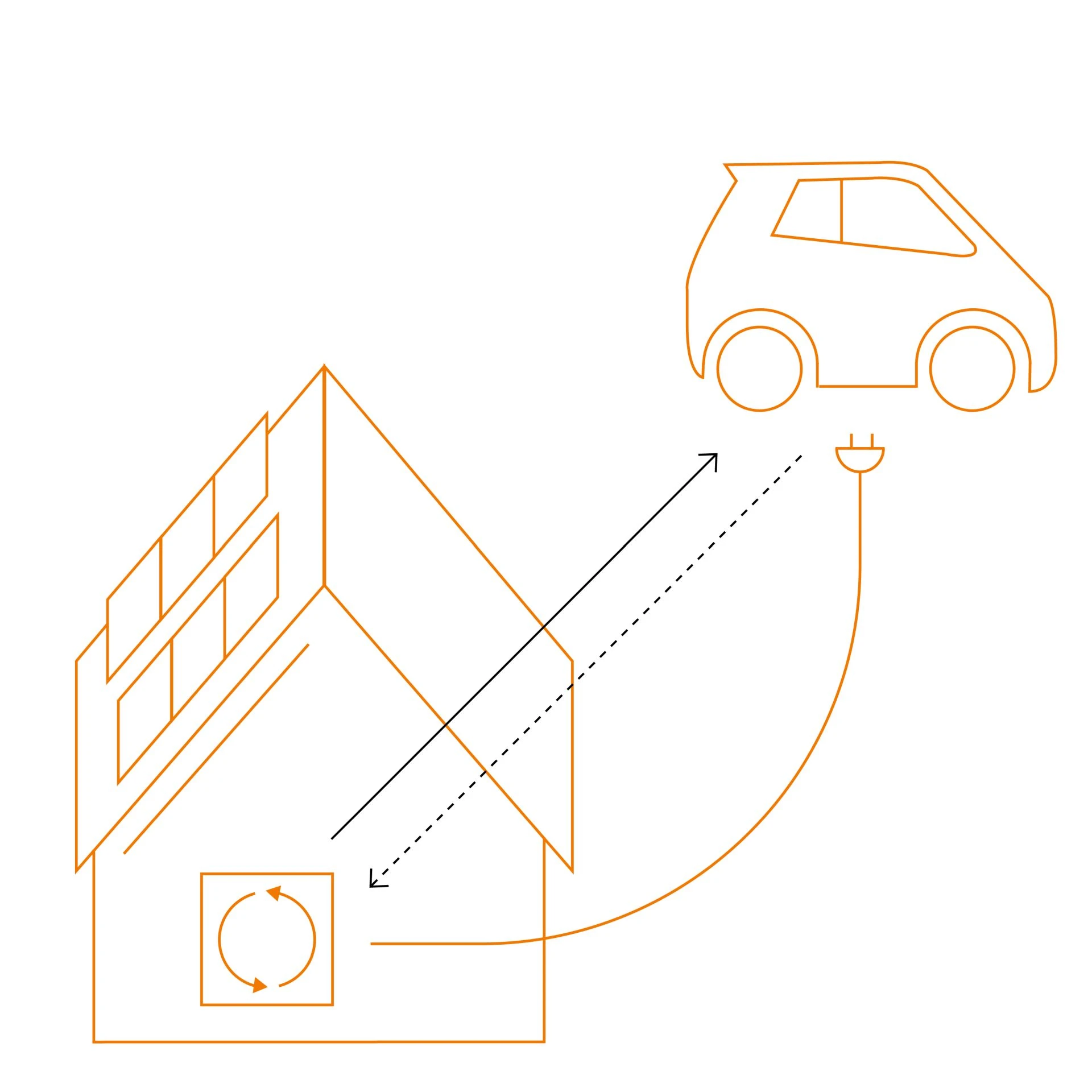

It is thus already possible for solar power not only to be fed from the roofs of residential buildings into the local grid, but also to be stored locally in the basement or sent directly to the electric car in the garage. The car battery could, one day, even be used as a storage device to lighten the burden on the national grid.

It is not only the energy sector that has come to rely on the Dürr subsidiary’s products, but also the aerospace industry. Satellites launched into space obtain their electricity from solar sails, i.e. photovoltaic systems. One thing that Roßkopf is particularly proud of is that the solar modules they contain are increasingly manufactured using machines from Freiberg am Neckar.

The power of the sun

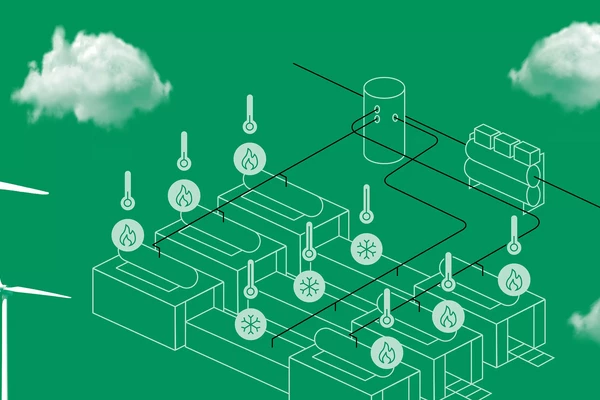

The energy system of tomorrow

The energy transition calls for change. To ensure a constant supply of renewable energy, the energy system of the future must overcome a number of different challenges. It needs, among other things, an intelligent connection between generation, distribution, and consumption of electricity. The storage of energy also plays a key role because more renewable energy means more volatility in the grid.

Photovoltaic system

Private individuals and companies use PV electricity to cover their own needs and feed surplus energy into the public electricity network.

Energy management

Energy managers ensure the demand-oriented and intelligent distribution of electricity as well as the most efficient use in their own household.

Sunny times

The sun is one of the most important energy sources of the future. Dr. Achim Kraft from the Fraunhofer Institute for Solar Energy Systems ISE sees huge potential for solar technology — provided that the companies in this industry continue to drive its development forward through innovation.

Just 20 years old, the photovoltaic industry is a very young sector. Nevertheless, it already boasts some remarkable achievements. With levelized costs of electricity of around 6 €ct/kWh, photovoltaics are among the most cost-efficient of energy sources. It is particularly in regions with high solar radiation where PV energy has already overtaken coal, gas, and nuclear power.

Going forward, the demand for electricity will rise steeply because households, vehicles, and industry are gradually replacing fossil fuels with electric-power-based technologies. It is estimated that Germany alone will require between 300 and 450 gigawatts of installed photovoltaic capacity for a fully regenerative energy system. Today, it has around 60 gigawatts.

To achieve this goal calls for enhanced products and more efficient processes. Thus, solar cells are becoming thinner, which saves material but requires new processing methods. In addition, more efficient solar cell technologies are being developed, such as the tandem solar cell. To interconnect these new-generation heat-sensitive cells, an electrically conductive adhesive is already in use today. This technology has additional benefits. An adhesive joint is more flexible, thus enabling it to absorb more thermomechanical stress than a solder joint. Dispensing with soldering also means there is no longer any need for lead.

These examples are just a taster of the opportunities that exist to make photovoltaics even better. They illustrate the importance of commitment, pioneering spirit, and the close cooperation between industry and research in this field. In the case of Teamtechnik, this has already paid off. It is partly thanks to the adhesive technology jointly developed with Fraunhofer ISE that Teamtechnik last year recorded its largest photovoltaics order in the company’s history.