Maintenance made easy: DXQequipment.maintenance

Apr 3, 2019

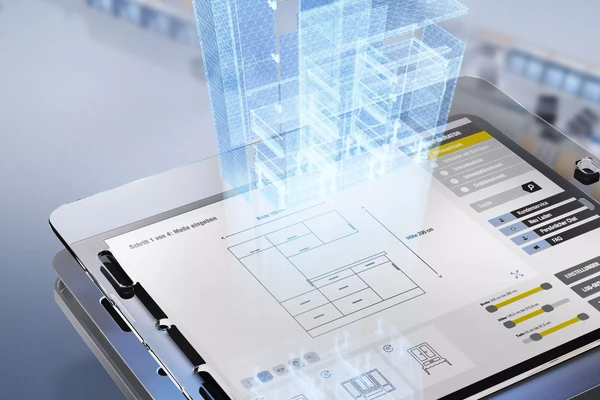

The DXQequipment.maintenance offers customers new possibilities for maintenance in paint shops.

In large automotive paint shops, there are thousands of components to be serviced, such as pumps, valves, filters and robots. The DXQequipment.maintenance (formerly EcoScreen Maintenance Assistant) keeps a record of every component. It shows maintenance dates, provides access to instructions, prompts completed work acknowledgement, and prepares a maintenance history.

What is special about the DXQequipment.maintenance?

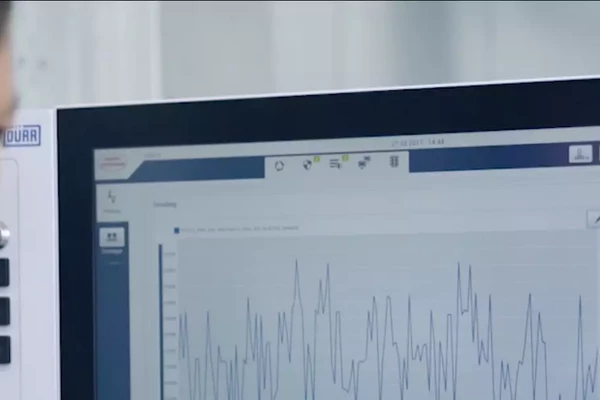

One unique selling point is that the software not only signals fixed maintenance intervals, but it also works on a cyclical basis. This means it counts how often a component has been used and calculates the remaining operating time. For this purpose, it accesses the controls in the paint shop to retrieve usage data.

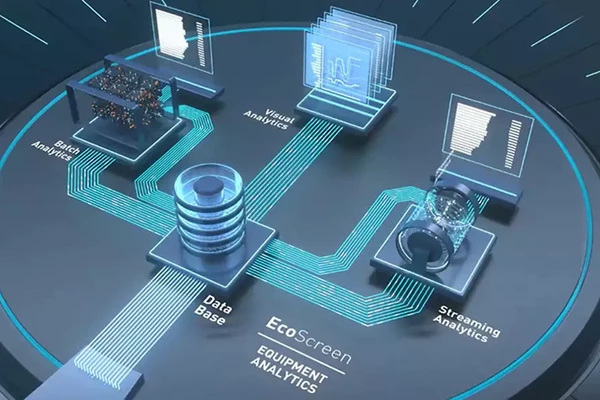

The → DXQequipment.maintenance is already being used in several automotive paint shops. Going forward, the application should also indicate predictive maintenance requirements. To this end, it will be linked to the → DXQequipment.analytics (formerly EcoScreen Equipment Analytics) software. This uses special algorithms to check for wear and tear of components, and transmits the result, along with a relevant maintenance task, to the DXQequipment.maintenance .

The new products include both current software technologies and Dürr’s special expertise in the painting process.

Ralf W. Dieter, CEO of Dürr AG

The two applications → DXQequipment.analytics and → DXQequipment.maintenance form another milestone in the digitization of production processes. According to Dürr CEO Ralf W. Dieter: “Our digital innovations are turning paint shops into smart factories. The new products include both current software technologies and Dürr’s special expertise in the painting process. This is how we are offering efficient solutions for the smart networking of the painting process.”

See how the two innovations for the Industrial Internet of Things (IIoT), DXQequipment.analytics and DXQequipment.maintenance, work together.

Traffic-light system indicates maintenance

Using a traffic-light system, the software simultaneously indicates maintenance that is due now and in the near future. The intelligent system bases the need for maintenance on the plant’s actual condition. This ensures high availability over the long term.

An illuminated green wrench

on the screen indicates that:

everything is fine.

If it is yellow, maintenance

should be scheduled

in the near future.

A red wrench means that

maintenance tasks are

required immediately.

The → DXQequipment.maintenance was developed by the Digital Factory. Founded at the beginning of 2018, this organization has cross-departmental software experts working on solutions for the digitalization of production processes.

Learn more about the work of the → Digital Factory and our strategy for Industry 4.0 → digital@DÜRR strategy.